I have been wanting to make my new bandsaw mobile since the day I got it. I contemplated designing my own mobile base but it just sounded like more of a chore than a fun project. Of the many commercially available mobile bases out there I decided I would purchase a Harbor Freight unit. It wasn’t until I had the mobile base in my online basket and my debit card in hand that I realized I didn’t need it. I already have a mobile base…my old table saw mobile base. Sorry Harbor Freight. Maybe next time.

Shortly after I purchased my table saw I made a new mobile base to integrate dust collection. This left the stock mobile base unused. It sat in one of the spare rooms of my shop quietly collecting dust until I decided to re-purpose it here. The height of the “new” base is about four inches lower than my bandsaw’s stock base. I thought about making a shallow box with drawers to accommodate the height difference but ultimately I decided the lower height would be a benefit. I’m a short guy (5′-6″) and I always felt that using the bandsaw put my shoulders in a permanent shrug position.

The table saw mobile base is a skeleton design with no top platform. The first item of scrap I found that resembled the same size was a salvaged MDF veneer cabinet door.

To hold it down I drilled one hole at each corner through the MDF and metal base. I didn’t need to go with a bolt here. A simple screw will hold it in place just fine as the only movement I am trying to prevent is lateral movement.

Transferring the bandsaw to its new base was actually pretty easy this time. Getting it onto its original base was a 250lb pain in the butt but moving it to a shorter base required a little slide and gentle rocking back and forth. Once on the it’s new base positioning the saw was easy. I chose to have the saw as far away from the lift foot lever of the base. This way it would be easier to lift as the weight would be closest to the fulcrum of the lift mechanism. To mark the new holes I roughed out the position with a marker and eyeballed the location of the holes. The stock bolts wouldn’t work here as they do not have the length needed to go through the added thickness of the MDF. I ended up using 5/16″ x 3″ carriage bolts that I had laying around. But I didn’t actually use the carriage end of the bolt. I used a series of nuts, lock washers, and flat washers in a way in which you would use threaded rod.

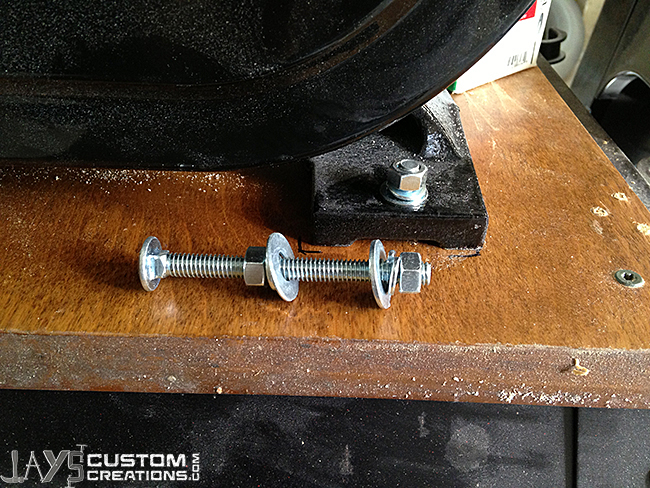

To mark the new holes I roughed out the position with a marker and eyeballed the location of the holes. The stock bolts wouldn’t work here as they do not have the length needed to go through the added thickness of the MDF. I ended up using 5/16″ x 3″ carriage bolts that I had laying around. But I didn’t actually use the carriage end of the bolt. I used a series of nuts, lock washers, and flat washers in a way in which you would use threaded rod.

With the saw bolted to the “new” base I absolutely love it. The saw is finally easily mobile and the best part is I didn’t have to spend a dime. I even have a dedicated miter gauge storage location now.  While I do use this saw a lot I will really like the fact that I can roll it away when it is not needed. For now its new home is where the refrigerator used to be in this “shop” and the newly freed up space will be the focus of my attention in the coming months.

While I do use this saw a lot I will really like the fact that I can roll it away when it is not needed. For now its new home is where the refrigerator used to be in this “shop” and the newly freed up space will be the focus of my attention in the coming months.

Very good. Mobility is the key man. I’ve begun building a mobile flip table for my plan and drill press. I bet the SOB was heavy. I remember bring mine out of my parents cellar after my dad died. I think I have body parts that have still not recovered.

Thank you Harold. When I put the saw up originally it was a PAIN in my rear…well actually my back. Boy can these tools get heavy quick!