Recently my friend Mike took the time to put together a shop tour for us. Check it out!

Starting from within, the shop is 500 square foot attached garage. The house is only 1000 square foot. The attached garage was a big selling point. Combined with the fact the garage was finished with epoxy painted floor, heat and air conditioning. The house almost sold itself.

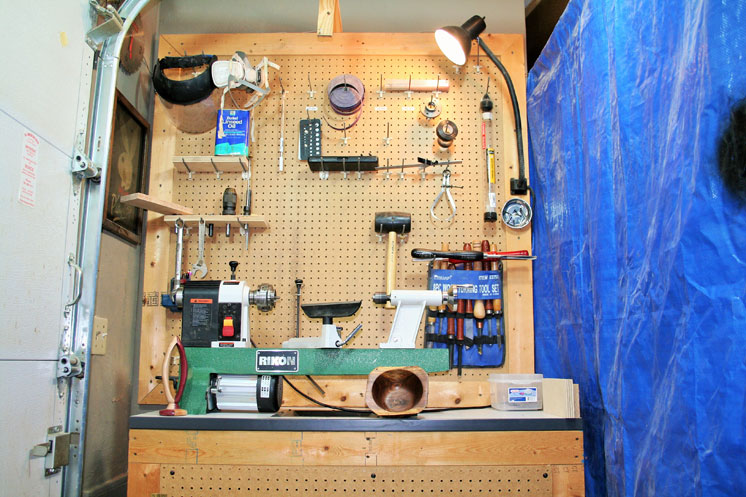

Starting with the left side coming into the garage door. My lathe area has worked out well, the 1 ¼” thick scrap table top makes a great mounting surface for the bench top Rikon lathe. I also have a short video showing this area.

The area underneath stores the well pump. I hung peg board frame with 2×4’s above the lathe for all the lathe tools and safety equipment.

The area underneath stores the well pump. I hung peg board frame with 2×4’s above the lathe for all the lathe tools and safety equipment.  Directly under the lathe I cut out for a dust collector.

Directly under the lathe I cut out for a dust collector.  This is hooked to a tube coming out the left side and hooks into the dust collector.

This is hooked to a tube coming out the left side and hooks into the dust collector.

Continuing down the left side of the shop. I still have to share some of the shop with the family so this section is the called the domestic section of the shop. The cabinet above the washer and drier with my wife’s initials on it.  This stores all the house hold cleaning supplies and shop radio.

This stores all the house hold cleaning supplies and shop radio.

To the right of the door is a station to iron clothes and a place to hang the dust pan and shop towels.I built the enclosed area around all the utilities: Furnace, water heater, water softener, ect… I remember just a little about my grandfather. I heard stories that he always kept a picture of his kids in his shop so have two picturess in the shop. One of them is in this area.

To the right of the door is a station to iron clothes and a place to hang the dust pan and shop towels.I built the enclosed area around all the utilities: Furnace, water heater, water softener, ect… I remember just a little about my grandfather. I heard stories that he always kept a picture of his kids in his shop so have two picturess in the shop. One of them is in this area.

I also have some of my grandfather’s old tools in this area hanging on the wall.

I also have some of my grandfather’s old tools in this area hanging on the wall.

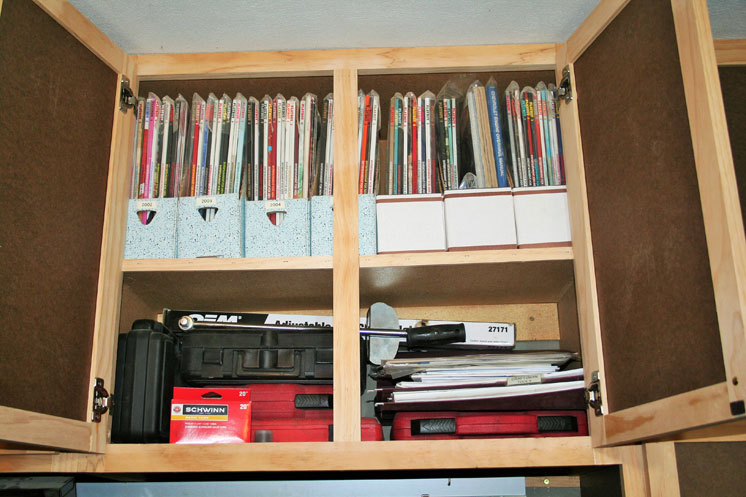

Along the back wall of the shop are matching cabinets and tool boxes along with my DeWalt planner and Delta bench top jointer cart. I came across a retailer getting rid of all the shelving units. They were selling the 12”x4’ MDF planks for fifty cents each. I bought every one of them. With this I built all new cabinets. I did the face frame and door frames with pine. The door panels are hard board. This was the start to a long journey of building my shop.

On top of the tool box I made a craft paint storage. You can see the video here.

On top of the tool box I made a craft paint storage. You can see the video here.  On the right side of the cabinets I have a small area that I put my clamps that I don’t use all the time.

On the right side of the cabinets I have a small area that I put my clamps that I don’t use all the time.

The Window wall or tool bench wall. This is the back drop to all my videos and the most active area in the shop and usually the messiest. From day one, I hung all the peg board and then started removing the old cabinets. Then I built the workbench across the window wall.

The router bit storage is handy.Each shelf slides out so I can take it to the router table. This comes in real handy if you are doing multi-bit setups for molding or frame and panels.

The router bit storage is handy.Each shelf slides out so I can take it to the router table. This comes in real handy if you are doing multi-bit setups for molding or frame and panels.

The bench also mounts my Rikon slow speed grinder outfitted with the Wolverine Grinding Jig. This makes it easy to make repeatable grinds on a lathe tool. Here is a short video on one way that I use this system.

The bench also mounts my Rikon slow speed grinder outfitted with the Wolverine Grinding Jig. This makes it easy to make repeatable grinds on a lathe tool. Here is a short video on one way that I use this system.

Now the work horse on the shop, my Delta contractor table saw. Equipped with the router inserted into the top and a unique out feed table. Here is a video that explains the reason for the gap between the saw and out feed. I also have a video showing my table saw and router area. The router has a homemade router lift copied from Steve Ramsey’s videos.

The router has a homemade router lift copied from Steve Ramsey’s videos.  Here is my 45 degree miter sled mostly going to be use for picture frames. Here is a video of it being built.

Here is my 45 degree miter sled mostly going to be use for picture frames. Here is a video of it being built.  And this is a custom jig to build snow flakes. These snow flakes were done by Steve Ramsey. Here is my version of them.

And this is a custom jig to build snow flakes. These snow flakes were done by Steve Ramsey. Here is my version of them.

Only thing I left out was my miter saw that I have on a roll around tool cart that doubles up as a pneumatic tool storage. I also left out my bench top band saw that I store under the out feed table of the table saw.

A big thanks and a thumbs up to Mike for showing us his shop. It looks like he’s got quite a nice setup! You can also subscribe to Mike’s YouTube channel here. It’s obvious that we all like checking out everyone else’s shop so if you would like your shop featured here let me know here!