The most common topic I get asked questions about is tools. And while I continiously tell everyone I do not like to talk about tools as I do not want my content to be all about tools I’m going to have to give in a little and start sharing my thoughts on some of the tools I do own to hopefully alleviate some of the repetitive questions I get asked (that doesn’t mean stop sending me questions! I’ll still respond). This week I’ll give you an overview on my planer and setup and hopefully within the next week or two I’ll have something to share in regards to my table saw.

Since using my planer in my half lap bar stools project I’ve gotten a huge wave of requests to explain my planer setup. So that’s what I’ll do here. But first I’ll lightly go over the planer itself and give some of my thoughts on it.

The planer I’m using is a DeWalt DW735. I’ve had it for about two years now and have mixed feelings about it. The easiest way to be direct about the issues is to do a little thumbs up thumbs down listing.

Thumbs Up:

- Strong motor. It chews through a full 13” wide slab with relative ease. You can hear the motor change pitch when it is faced with a wide slab but it’s never bogged down on me.

- Height adjustment is flawless. No complaints there.

- Has a thickness gauge to let you know where you are at. I have a piece of 5/8” melamine shelving in the bed so I have to subtract 5/8” for an accurate measurement. Not a big deal.

- Fan powered chip ejection with dust collector hookup. It also has a smaller port adapter that I suppose will fit a shopvac. I don’t have a shopvac so I can’t speak for that part. The fan motor is a beast though. You don’t need a dust collector with this setup. Just pipe the exhaust port into a filter bag. I’ll get into that later in this article.

- Benchtop model so technically it is portable. But there is a caveat with this…

- Readily available upgrades and options on the internet (blades, helix option, infeed outfeed tables).

- Snipe is controllable.

Thumbs Down:

- It’s a benchtop planer but the fact that it weights 92 pounds makes it a lot less mobile. Yes, you can pick it up and move it but it’s definitely a “set it and forget it” planer in my opinion.

- It’s quite expensive for a benchtop model. At the time of writing this article you can get it for about $500 USD.

- The DeWalt brand blades have a very low lifespan. I don’t use mine that often and after two years im on my third set of blades. At $55 per set this can get expensive.

- You can’t sharpen the blades as they are installed via index pins that do not allow height adjustment. Some have said they have sharpened theirs but I’ve had no luck.

- A lot of people have had issues with the rollers not properly feeding the material. I’ve never had this problem but I have also modified the bed slightly which would reduce this.

- Right out of the box, snipe is horrible.

Should YOU Buy This Planer?

While I do have Amazon affiliate links on this page in the slim chance that someone actually purchases it through me…..I’m not going to tell you that you should or shouldn’t buy anything. That’s not my decision to make. I honestly don’t care and have nothing to gain or lose from DeWalt if you do or do not buy this planer. It’s an investment that you need to research, evaluate, and determine on your own. That being said, I would not purchase this planer if I had to do it again. The reason being is purely financial and has nothing to do with the great performance of the machine. The DW735 is a money pit in my opinion. It’s not a one time investment due to the cost of the poor quality, non sharpenable replacement blades. I understand that with every planer you will eventually have to buy new blades but these have an incredibly short lifespan that cannot be stretched due to not being able to sharpen the blades. Yes, you could upgrade to carbide blades but even then its a larger investment. Yes, you could upgrade to a helical cutterhead for the planer but even then you are nearly doubling the cost of the machine. I’ve got about $650 in it after two years. If I were to do it over again I would take one of two paths. Either buy a much cheaper benchtop planer that allows sharpening of the blades and use the extra money on another tool for the shop or save up a hundred more and get a Steel City helical cutter head benchtop planer.

My Planer Setup

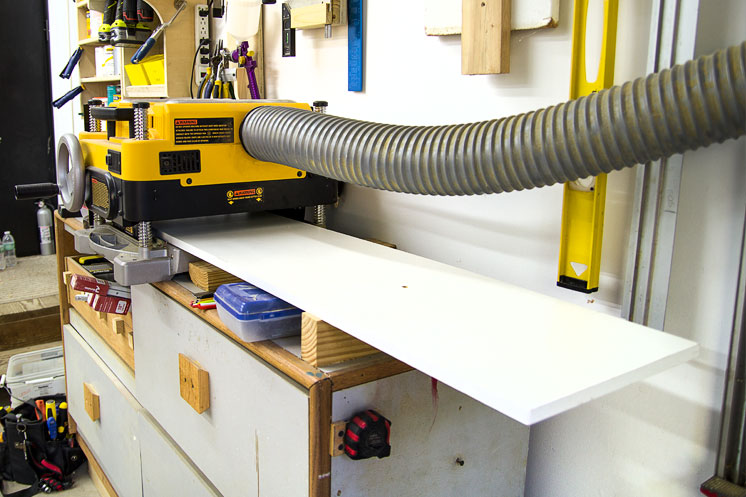

On with the show. I’ve had my planer sitting on top of a junk dresser I found in the trash for about a year and a half now. I love this setup and highly recommend it for anyone who is looking for a decent planer setup and has the room. Either build or find a dresser shaped piece of furniture. This allows a perfect shaped top surface for the planer to be secured to and do it’s work. And also, because there are drawers below it’s a great way to utilize storage space in the shop.

I didn’t take any exact measurements but I believe my dresser is about 5 feet long. On the top I have two chunks of 2×4 screwed down to the top of the dresser directly on the front and back side of the planer. This prevents the planer from sliding without actually screwing or bolting it to the dresser. On the ends of the dresser I have two more chunks of 2×4 to support an auxiliary bed that I use through the planer.

To extend the bed of the planer I used a 6′ piece of melamine shelving and slid it through the planer. To secure it I have one screw through the melamine and into the chunk of 2×4 on both ends of the dresser.

As mentioned earlier, there is a 4” dust port on the back of the planer that makes dust collection a breeze even without a dust collector. I use a short piece of Harbor Freight 4” dust collection hose here. No clamps needed. Just slide it on and forget about it. I’ve never had it come off during use even when my collection bag was full.

The flexible hose goes to a 4” sewer and drain 45 degree PVC fitting. From there a short section of 4” pipe is used with the bell end on one side. A regular pillow case is then secured to the pipe with a bungee cord. This is by no means a low micron dust filtration option but I find that nearly all of the waste from a planer is larger chips and this pillow case does a fantastic job at holding it all. Even with the bag full the planer has no problem shoving more chips into the bag and slightly compressing what is in there. All the junctions in the flexible hose and PVC are all slip connections. Nothing is secured with tape or clamps.

After playing around with the planer shortly after assembling this setup I completely eliminated snipe. Then gradually snipe returned on the infeed side of the cuts. It wasn’t until I took pictures for this article that I realized why. To reduce snipe everyone recommends ramping up the infeed and outfeed sides of this planer. That only works if you have auxiliary tables. So what I did was I cut my support blocks for the melamine shelving about 1/8” higher than the bed height of the planer.

It’s hard to notice at first but here you can see the outfeed side of the melamine auxiliary bed. At the planer the melamine is slightly more than 1/16” higher than the original bed. Something must have settled because I just noticed on the infeed side the melamine bed was bottomed out on the planer bed. That means I just need to shim the 2×4 support block on the infeed side and snipe should be reduced or eliminated again. Because the auxiliary bed is essentially suspended a slightly greater force is needed by the rollers to push the material through. I’ve never had any problems with the rollers not feeding the material through as they should with this setup.

Well I hope that helps out in some way. You can do this with any planer and I’m sure it will help out with snipe. If you found this article useful I’d love for you to share it for others to find helpful as well. Helping me reach more people greatly helps me to produce more free content in the long run. Thank you, good luck, and have a great day!

A couple of years ago I bought a new planer and limited my choices to “portable” ones just because of space issues. I did consider the cost of blades since most of them are disposable these days. Of course it’s hard to know how long they are going to last other than online reviews, but then you don’t know if the reviewer really knows what he’s doing or talking about. Personally I can’t see buying a helical head for a portable planer. If you’re going to invest that much money it’s not much more to get a “real” 15″ planer. I ended up with a Delta and the blades were only about $40.00 a set at the time. Thankfully I stocked up as they’ve gone up a good bit since. I have gotten good life out of them IMO. However, I had to send the first planer back due to a quality control issue at the factory. The belt pullys were misaligned and ate the belt in about 10 minutes. Customer service said there was no adjustment. The second one has been good, but I’m done with Delta as their quality has definitely gone down hill lately.

If I ever get the shop cleaned out and make enough room I’m going to get a Grizzly 15″ and put a Byrd cutterhead on it. That will be about $1,800.00, but it should be the last planer I ever need and years before I have to spend money on replacement carbide inserts. I have a jointer with a helical head and one of the greatest things is it’s very quiet. I don’t even need hearing protection when I use it. The Delta benchtop screams like a banshee and is the loudest piece of equipment in my shop, including my CNC.

Thanks Jay. Funny I was just looking at this model yesterday and almost pulled the trigger. I am glad I saw your story before hand. I think I will go with the steel city. A little big more initially but it has great reviews and the cutter head will be great.

It’s still a decent investment. Make sure its the one you want before you pull the trigger.

Jay, am I understanding correctly that the melamine bed is 1/8″ higher at the two ends than it is at the bed, and that this eliminates the snipe?

Yes. If you use a regular planer with the factory bed and put upward pressure on the board as it comes out you will reduce snipe. This is the same concept.

Personally, I think tool review is a good thing. After watching many of you on YouTube, we watch for the tools y’all use. Its by far a better review than what is under the tools on say, home depot. Hard to believe all of those statements are true. When you have someone who we see physically use a tool, over and over again, there is a more honest review going into it. I have also noticed you using your ryobi jigsaw more now then your Bosch, any reason there?

I prefer cordless. Brand name doesn’t matter a whole lot to me in that area.

I have been taught to cut your boards a little longer than needed. Then trim the ends off to get rid of the snipe on the ends.

Good tip, Mike.

Be aware that some of the Steel City planers have two sided cutters and some have four sided. Also, they only have 26 cutters whereas the Byrd 13″ cutterheads have around 40 cutters. The Steel City cutters are also HSS rather than carbide, although apparently aftermarket carbide replacements are available.

From my understanding a nice carbide set is cheaper than the HSS Steel City replacement set. I read that in one of the Amazon reviews..

I found the Steel City Helical planner for $100 less at Woodcraft. It’s posted at $499 plus $19.99 for shipping.

http://www.woodcraft.com/Product/2021202/25653/Steel-City-13-Portable-Planer-with-Helical–Head.aspx?refcode=10INGOPB&gclid=CjwKEAjw-o6hBRDOmsPSjqakuzYSJADR2V3SeUzj1mSyNoz3iZhz7TPrnGLemHODQTt0LMKTRzSBRRoCUHfw_wcB

I’m one of those who pestered you about this writeup because I own a DW735. THANK YOU for showing your setup and giving me some guidance on how to tame snipe. It is TERRIBLE on my unit without any extra infeed/outfeed support.

Thanks for sharing the details of your setup. I plan to copy it shamelessly.

Thanks for the review… I was seriously considering the DeWalt but now I looking for the best deal on a Steel City. I have learned so much from your Sketchup tutorials… you are a multi talented young man.

I just received a foley stationary planer that needs new belts and a cleaning of the table and I have to run a 220 plug to where ever I’m gonna put it

I have a 735 and I really like it. Without a melamine board in the bottom, I pretty much get zero snipe. When I recently added a melamine board so that I could plane a thin board. I got really bad snipe. So in my case, using the factory bed, I get very little, or no snipe. One thing, for short boards, do no touch the board on the outfeed end until it is fully through the cutters and rollers. If you reach for the board before it clears the cutters, you tend to lift it slightly, which will result in some snipe.

I think the 735 has been proven they standard in multiple tests when compared to other 110v planers… and when compared against 220v planers it can hold its own if you do not factor in a wider width with the bigger planers

I think the negative about the snipe out of the box it misleading because dewalt does sell in-feed and out-feed tables for the planer for a reasonable cost if they just included them with every planer they could stop some negative reviews before they happen… but YES you need in-feed and out-feed tables or a home-made solution on the planer

I had good luck with the factory blades but when it came time to replace them I did bite the bullet and put in a Byrd carbide insert head… why did I do this ?

well I can not go 220v in my shop no way no how at this point so I am stuck with 110v tools… and this with the Byrd head is the best planer I could get that has the build quality to last.. is stable enough in design and lifespan wise to get parts it it does break and has support for other manufactures for replacement blades and cutter heads

yes it is big and expensive and if I was moving it from job site to job site then I might choose something smaller but for someone else in the situation I am and wanting a stable planer that will preform to the level of a bigger 220v planers then you cannot go wrong with this platform… upgraded cutter-head or not

the wixey digital thickness gauge upgrade is also a must for me and I would never want to use the planer with out this addition as well

Jay,

Is there any rhyme or reason as to the length of the infeed/outfield table insert or did you just make fit the entire length of the bench? I’m in the planning stages of my planer bench and was wondering about how long to make the insert?

Thanks

Scott

That’s just the length I bought. I figured I would just use the whole thing. Since making this article I no longer use this setup. I put the planer on a short cart to store in the corner out of the way when not in use as I realized I barely ever use it.

The only steel city machine I can find is this one: 40100-T2 – 13” Portable Planer.

Did they discontinue the others?

Do you mean No snipe at all? Like you can’t feel any? I feel it perhaps 0.002″ or so. Is that acceptable for this machine?

Can anyone comment? Dewalt is telling me (repair depot) the one I have is as good as it gets. But then people post “no snipe”… ?? Do they mean NO snipe or they ignore this small amount of snipe?

I haven’t used mine in 6 months. I would say I couldn’t feel any with the setup mentioned in this article. I’m sure there is a minute amount but I couldn’t tell.

I found the dealt infeed and outfeed tables on tale and then mounted this beast to a Rigid miter saw utility vehicle. The cart has rollers on the infeed and outfeed sides so along with the tables you can get great results. Also with the cart I can fold er up and store it out of the way. I agreed on the blades. Waited until I got gift cards for Homer Depot and bought an extra set.

I must have a newer setup than you do, I also purchased the in-feed out feed tables. Now for me this is just a planer that is holding me over for the Powermatic 209HH which is quite expensive. In your review you stated that some have problems with the rollers not working all the time but you didn’t have that problem. I us-ta have that problem with mine, then I bought a joiner and it fixed it and now I no longer have that issue. The board is completely square now when it comes out. I have had my planer for over 4 years now, and used it on some very hard wood, recently I ran a little hickory threw it, but mostly I run maple and cherry threw it. I have ran about 1000 board ft over all I believe, so for the home shop, or hobbyist like myself these are awesome units. Those who need to do this sort of thing for a living should buy products specifically for making a living. I don’t buy a 1/2 ton truck when I need a 1 ton truck, what you experienced was a hobbyist grade piece of equipment ware out quickly doing probably pro level work. If you bought a 209HH you wouldn’t have to write a long review like this one. Don’t get me wrong its a good read, but I wont be in a hurry to replace mine with anything steel city makes… That thing you suggested might be OK, but I’m glad I bought the 734 its done me well. My point is I knew what I was going to do when I bought my truck 13 years ago, it still works fine. I bought my joiner its a 8″ PJ-882HH which is a phenomenal piece of equipment. If my kid has a kid, and my kids kid has a kid, he/she could be using that PJ-882HH when they are 80 years old… Its a great piece of equipment, and if your doing pro level stuff, maybe you should look into pro level gear. When a proper planer is $3000 you shouldn’t cry about a $500 cheap planer. It will be a long time before you purchase enough blades to make up the difference. I would say you gave it a fair review in your eyes, and that is a good thing. I don’t believe I want a piece of equipment made by woodworkers, just the same as I don’t want to work with metal. That’s akin to doing auto work yourself when you know you need to take it to a mechanic.

Thanks for the review Jay, I was going to write you and ask why you selected this machine but now I know. I’ve been torn between this and the smaller brother 734, think I’ll save some cash and go with the 734.

Jay, first off let me say how much I enjoy your videos! Like you and others have mentioned, out of the box I too had problems with snipe and later with the feed as well. For the snipe I saw and copied your shelving solution and it has worked great! As for the feed problem I’ve found if a person keeps the rollers clean it pretty much eliminates any problems. I included a link showing how I capture the chips/dust.

http://lumberjocks.com/projects/100027

Thanks again for all your great videos and tips!

Jay, I have an opportunity to buy a 735 for $200 that is 10 yrs old and frankly, never used. Know seller. Bought for a specific setup that never occurred. Meticulous about his equipment and this thing does look new. My concern that others have advised me that the machine is extremely loud. Yet I see you have it in a garage setup much like my own. I would be using a thickness planer mostly for cutting boards and small projects. Looking strictly for benchtop. Don’t want to drive the neighbors away with noise in the garage. Fairly new wood worker and gaining respectable shop piece by piece and increased difficulty of projects. Been told, get a planer! Certainly save on hours of sanding I do.. Or do you have another recommendation?

I have a DW 375 planner and the fan was wore out, I replaced the fan but have had problems entry since, fan will blow out port but all of the chips are plugging up machine out side of the shroud assembly. Does anyone know what is the problem