A lot has happened in 2018. My family life leveled up and so did my shop. And as the year comes to an end it’s only fitting to do yet another shop tour of my current shop. I’ll cover that next week most likely. This week I wanted to hit the pause button and go back to where it all began. So many people like to complain about bad situations for their hobby or let small circumstances get in the way of them doing what they want to do. Or not having this tool or that setup to get the job done. The truth is that we all start somewhere and the beginning rarely smells like roses. This article will cover the first space that I was able to call “my shop.”

Before I talk about my first shop I want to give a little context of how it came to be. For years I was a back seat subliminal sponge to the debt free teachings of Dave Ramsey. “Where debt is dumb, cash is king, and the paid-off home mortgage has taken the place of the BMW as the status symbol of choice.” Over…and over…and over…and over I had to listen to Dave while being a kid stuck in the back seat. When I was 18 years old my mom started charging me rent. Wasting money on rent? As an 18 year old I thought it was crazy. It’s a never ending payment. A bad investment! So I got a job and saved up as much money as I could. I bought an acre of land and found an old house trailer that was in such bad shape that the owner said if I move it I could have it. I did the necessary work to put borrowed axles and tires under it, removed all the blocks and tie downs, and paid a moving company $440 to move it onto my property. It was a 2 bedroom one bath single wide piece of junk that was dropped off in the middle of my property with the tongue sitting on a stack of cinder blocks. My uncle and I positioned it on my property with my grandfathers old beast of a pickup truck. At 19 years old I was a land owner, owned the leaky roof over my head, had two junky vehicles and was 100% debt free. The life of a king :)

There’s a catch to the “roof over my head” statement. The trailer was (and still is) in horrible shape. If I lived in the city limits it would probably be condemned. When the moving company moved it a 6′ wide section of the exterior wall tin flew off. It was on the back of the trailer in the master bedroom. Just 2×3 wall studs and the open air outside. I never fixed it. At the time I didn’t really know how to and honestly did not care. I put a tarp over that missing wall section and another tarp over the back side missing windows in the living room. I lived in that trailer for six years listening to the tarps flap around every time it got windy. The tarps were on the back side of the trailer which was pushed up against a tree line. They never received sunlight and held up quite well. The master bedroom was used for miscellaneous storage. And the living room was gutted on the inside before I got it. 100% of the floor in the entire trailer was spongy and falling in from all of the roof leaks. I spent a little more than $700 to cover the entire floor with 3/4” CDX plywood, patched the roof leaks as necessary, and heated and cooled the small bedroom and the bathroom. Everything else was was left unimproved. I was a bachelor, debt free, only had an electric and car insurance bill every month, had a low paying job making more money than I was spending, and nobody could take it away from me.

I looked for any pictures of the trailer and this is the only one I could find. Sometime in 2013 I used Photoshop to put my old logo on it. I think this photo is originally from 2010. There she is. Home sweet home.

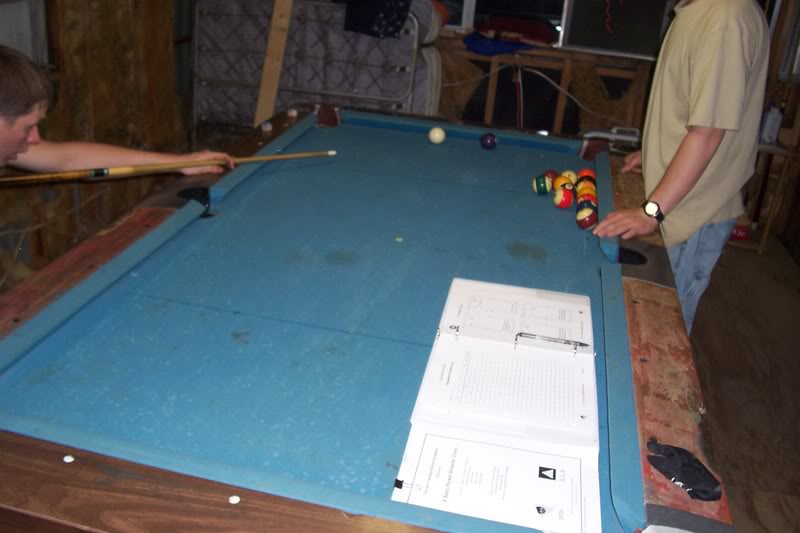

Inside the living room used to be a pool table. I had a 1960’s (I think) 6-1/2′ slate top bar box pool table. It was really tight but allowed me to stay in stroke shooting corner to corner. That’s me on the right and my long time friend Jeremy on the left. You may have seen him in a few recent videos. To this day we still shoot pool and I’ll still give him the last two (I hope you see this, Jeremy hahah)

Shooting pool was my life. I didn’t gamble much because the risk was too much for the amount of money I made but I did play in a lot of tournaments. I got to a point where I was making more money playing in pool tournaments and replacing cue tips and ferrules than I was making at my job.

In 2008 the economy crashed and nobody could afford to play pool anymore in north Mississippi. My hobby no longer provided income so I took an unplanned path. I sold my pool table, cues, and 7×10 mini metal lathe setup for replacing pool cue tips and ferrules and bought woodworking tools. I went to Lowes with around $600 in hand and bought a bunch of Skill brand tools. I came home with a benchtop table saw that scared the crap out of me, a router table that I didn’t understand how to use or why I needed it, a 9” bandsaw that barely cut, and a few other items that I can’t remember. I knew I previously saw variations of all of these tools on The New Yankee Workshop show with Norm so they had to be used for something. I was going to figure it out.

The benchtop table saw was dangerous. It vibrated around so much that I had to put my foot on the lower horizontal member of the flimsy metal stand it came with while making a cut. I had no idea how to use a table saw and did no research on safety but I do recall never standing behind the blade while cutting. Not for safety but rather to prevent the sawdust from being thrown in my face. I remember having the saw setup in the middle of the living room with me facing the end windows and my wife (girlfriend at the time) and step-dad behind me watching a hockey game in the kitchen area with their backs to me. I told them it was going to get loud for a second while I made a cut real quick. I turned on the saw to cut a piece of plywood and without realizing what even happened the small square of plywood kicked back and shot across the room behind me. It didn’t hit me or anyone in the room but I was terrified. I didn’t even know what kickback was at the time. I turned the saw off and asked them if they saw the piece of wood that went flying. They were so immersed in the hockey game that they had no idea what I was talking about. I quickly developed a greater respect for a table saw and researched why that event happened. To this day that is the only time I’ve been scared at a table saw. Live, learn, and proceed more intelligently next time.

The 9” Skill bandsaw didn’t last more than a few days at my place. I returned it because it barely cut anything. At the time I didn’t realize how much of the performance problems were due to the blade. I just thought the saw itself wasn’t good. I returned it and didn’t have another bandsaw until I got the Grizzly G0555LANV in the apartment shop a few years later.

Those Skill brand tools were the start of the woodworking infection for me. I slowly upgraded here and there until I got a pretty decent set of tools to work with. The following images represent the best state of my first shop. Here is my entire first woodworking shop setup in the living room of my first home. The ceiling was sagging, the interior walls stripped, a tarp over the back wall windows, the floor sinking in the back right corner, but the roof kept water out and it had electricity :)

This is my very first miter saw station. I found an old dresser of some kind and put some 6” industrial casters from my grandfathers junkyard on the bottom. The saw on top is an old 10” delta belt driven miter saw. That miter saw was HEAVY but it worked great. I secured a couple elevated platforms on top of the station. The miter saw down below is a lightweight Makita 10” miter saw. I don’t recall how I acquired that one or where it went. The best thing about this miter saw station was the dust collection. When cutting the saw would shoot the dust through the missing window, bounce off the tarp, and fall to the ground outside.

Moving past the miter saw station I had some miscellaneous wall storage and a metal rack for chemicals. One spark and this corner would have probably burned down my entire home. Keeping all of these chemicals open like this wasn’t smart at all.

The end wall of the trailer had a collapsing bay window and a bad floor below. I built a workbench in this corner to stop me from stepping in the weak spots and to store a bunch of crap below. It’s hard to tell but I think I had a shopvac, air compressor, and a few tool boxes below. Plus a few boxes of hardware here and there.

Moving to the right was my radial arm drill press, my “nice” table saw, and a wall mount storage bin system. These windows went to my front yard and for privacy I spray painted them black. It was cheaper than blinds. Disregard the dangerous electrical wires everywhere…

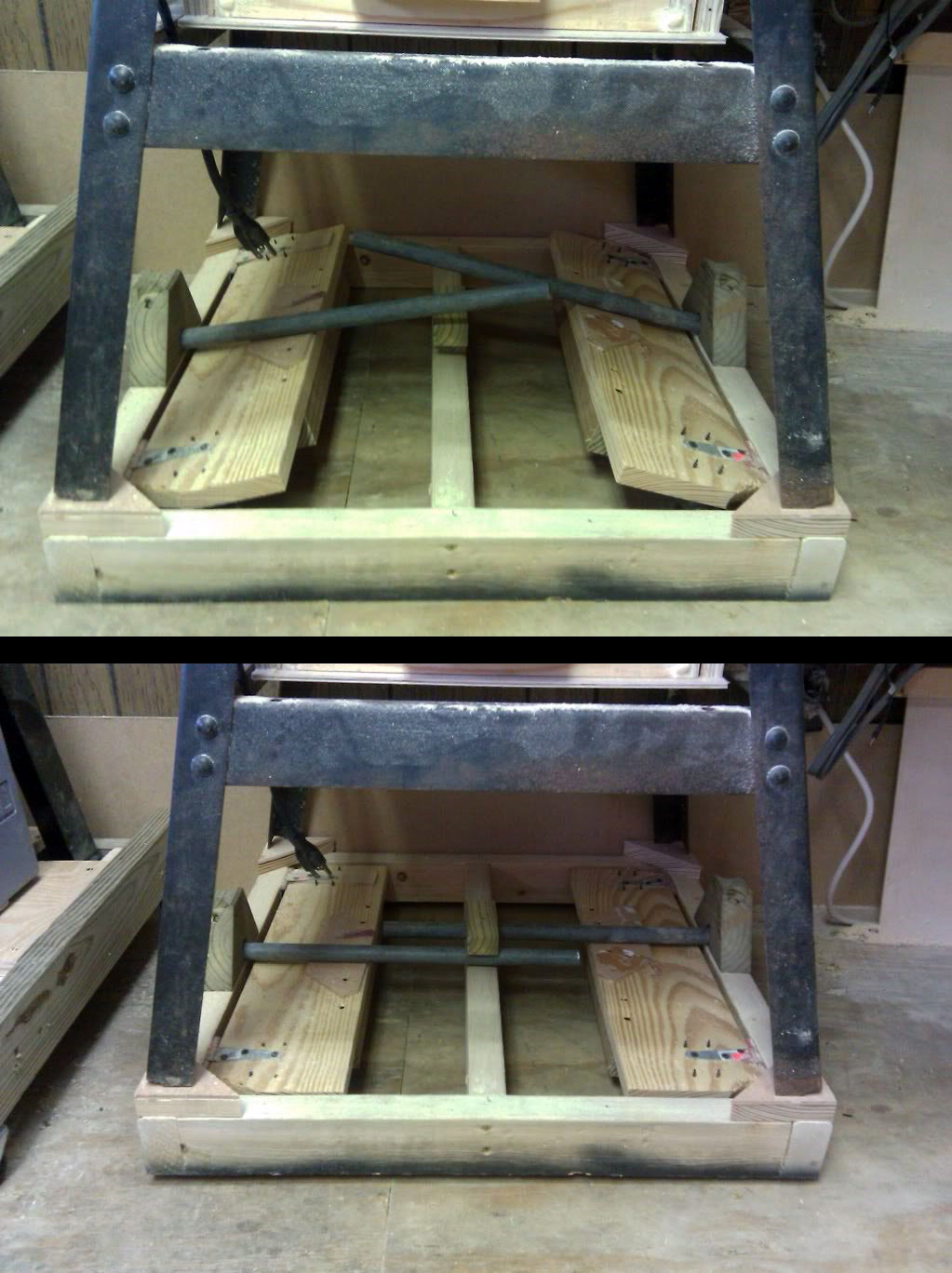

About that drill press.. This was an interesting machine. I don’t recall what brand it was but the head moved forward and backward with the same style mechanism as the table platform. I didn’t have the same standards for tool precision back then as I do now but I do remember it drilling quite nice. The base it came on had a shelf for storage. I built a small rolling base for it and loaded it up with junk.

You can see the base got modified a few times.

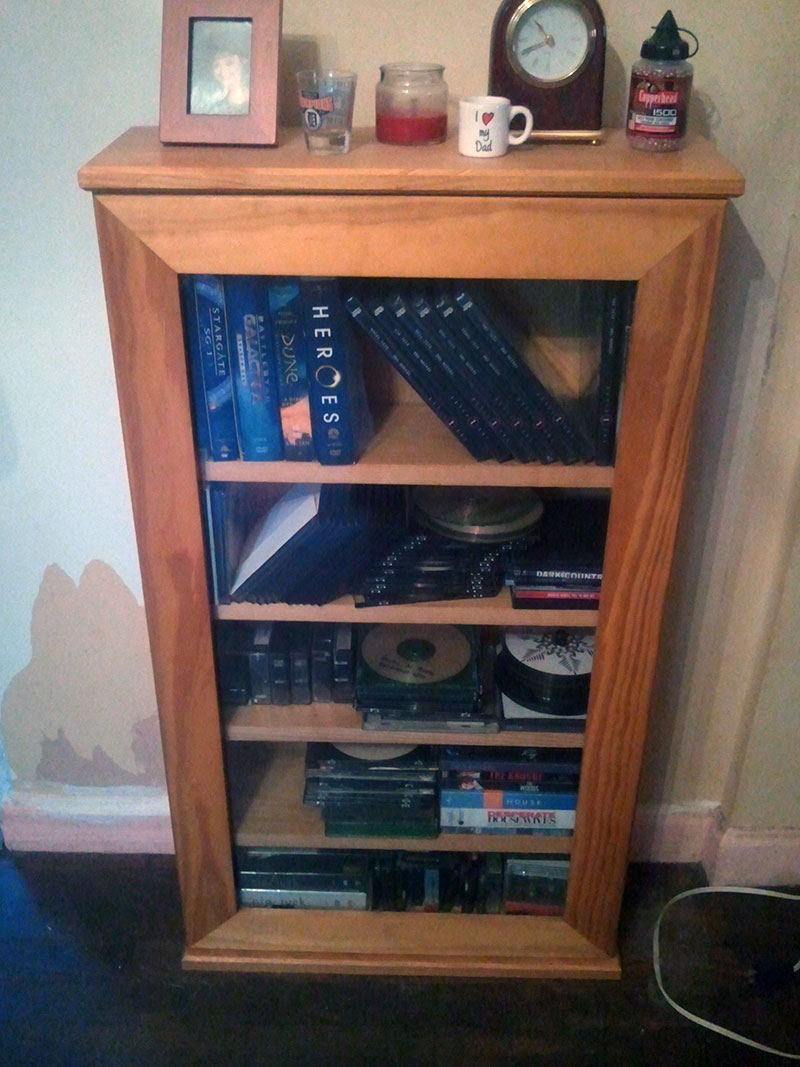

This is the best image I have of the best table saw I had in that shop. It was an old Delta Super 10 table saw. The fence was horrible. I used a straight edge against the blade to draw a line on the cast iron surface and then had to measure away from that line on the front and back of the fence and lock the front and back independently. It got the job done but was by far this saw’s weak link. The saw was a huge upgrade from the Skill that I bought brand new and the best part was that I only had a few dollars in fuel invested in it. I won a propane grill at my work’s company picnic and traded it for a Marlin .22 tube fed gun and 40 or so pieces of 1′ x 4′ x 3/4” CDX plywood and then traded the Marlin .22 even for the saw. Even though the saw was old the blade ran smooth and it cut great.

I saw this mobile base design on the internet. It worked rather well. The pipes would force the casters down and locked in the middle. To lower the saw the pipes would be pulled out from the center lock and the casters retracted.

Those are the few pictures I have left of my first woodworking shop. It wasn’t anything special but it was a lot of hard work and sweat that allowed me to really make stuff for the first time. So when I hear that “it must be nice” to have the tools I currently have or “I can’t do this or that because I don’t have this or that” it upsets me. Not because of any negative energy towards me but because people are losing their sense of pride. People are settling for less and complaining more and more about what they don’t have. If you want something then get off your butt and earn it. It’s hard work, everyone’s journey is different, and anyone can do it. And yes, it’s pretty damn nice to look at my shop now and see the results of hard work.

All of the tools in that shop were eventually sold to fund rebuilding the engine in my truck. I had no oil pressure and found out the cam bearings were shot. I couldn’t afford to have it fixed so I sold off everything in the shop to avoid debt and my uncle and I rebuilt the entire lower end of the engine. It wouldn’t be until building the apartment shop 3 or 4 years later that I got back into woodworking. I’ll leave you with the few pictures I have left of projects made in that shop.

Comments are closed.