So much has happened since I started casually remodeling my office. Casual is the key word there. Not only have I not given it much priority but I’ve also had a few good things happen with life and with the business in the meantime. And with that said, making this bookcase was one step closer towards calling the office remodel complete. If you’re interested in a set of plans for this bookcase click here.

Everything I’ve made for the office so far has been very basic from a design standpoint. I simply do not want to put a lot of time and effort into making fine furniture for this space because I know I have to share it with four of our dogs. This bookcase design is simple as well. It’s a tall bookcase with a fixed shelf dividing the upper and lower areas. In the upper and lower areas are two adjustable shelves. The main joinery method for the bookcase is pocket hole screws and the main material is plywood, specifically 3/4″ PureBond birch plywood. It’s made here in the USA and sold at the Home Depot.

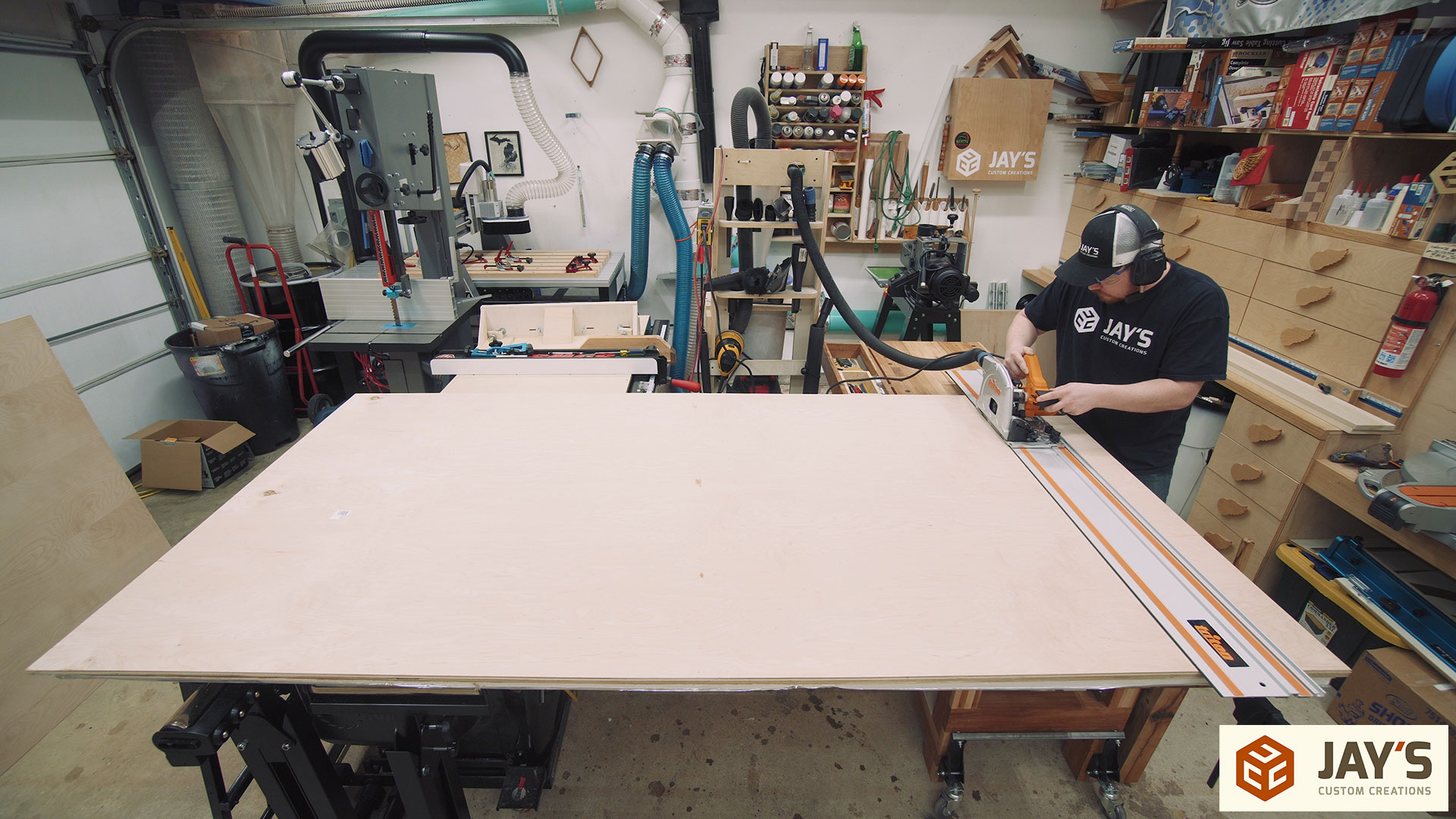

Step one is to break down the sheet of plywood. To start I’m making a full width crosscut with a track saw to remove a small section of material. This kind of cut is possible on a table saw but it’s not easy and can sometimes not be safe due to the size of the sheet and the small amount being removed.

Followed by a nearly full length rip cut. Making a cut like this on a table saw isn’t as sketchy as the last one but with it still being nearly a full sheet it’s another situation where bringing the tool to the material is easier than bringing the material to the tool.

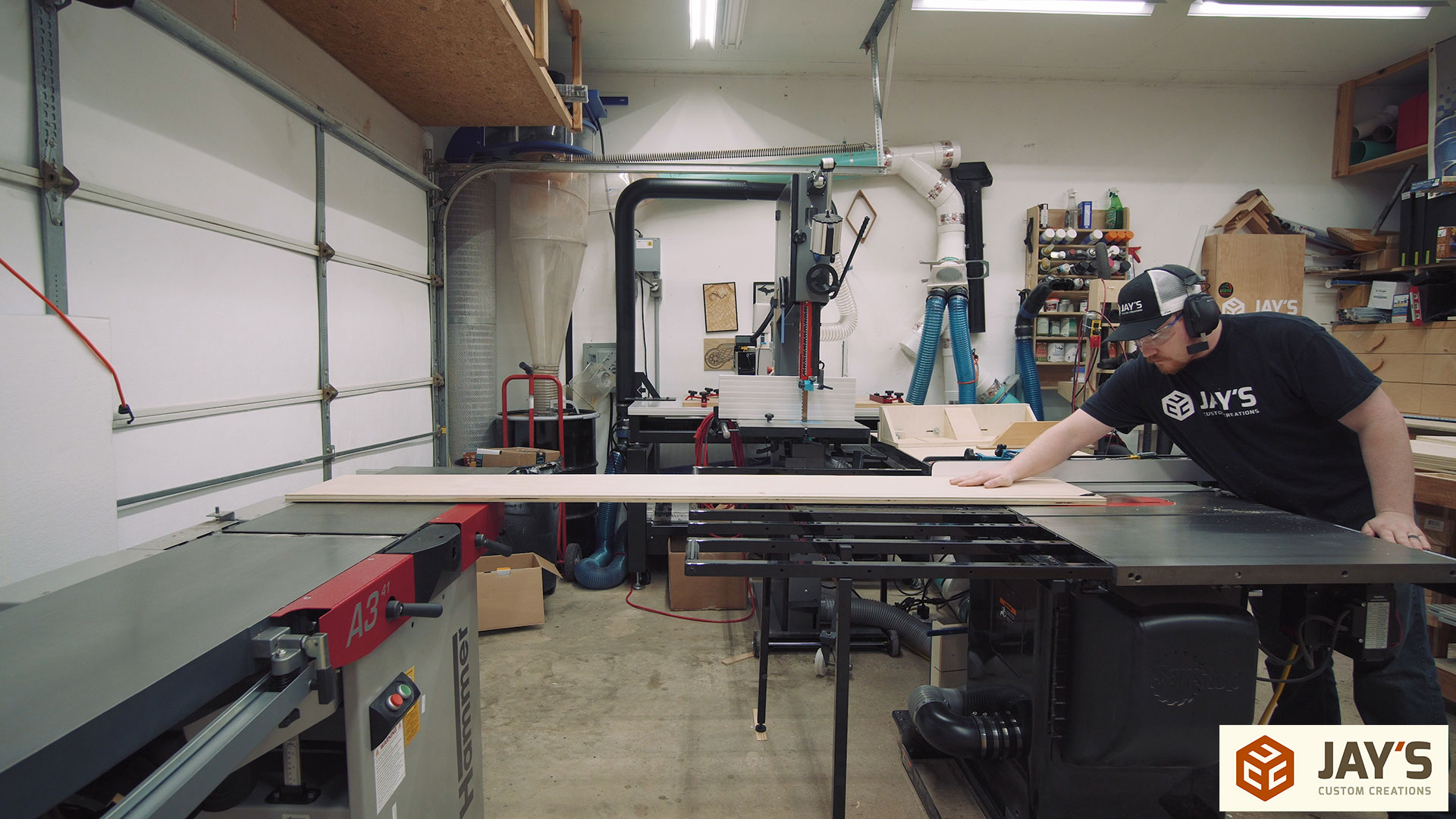

And now the more easily managed pieces can be brought to the table saw. I made a set of plans for this project before I started so the rest of the plywood cuts went by pretty quick.

There are a total of seven horizontal plywood pieces for the bookcase. The three on the right are for the fixed top, bottom, and middle panels and sized a little wider than the four on the left in this image. Those are for the adjustable shelves. They will eventually have solid wood banding installed on them.

Here you can see the importance of having as many horizontal surfaces as possible at the same height. In order to make 8′ long cuts I need to remove the fence on my jointer/planer. Not a big deal :)

Before assembly of the case I got started on the face frame material. All of these pieces will be cut from s4s poplar. Every time I buy s4s (surfaced on 4 sides) lumber a little piece of me cries. The whole point of having machines for milling rough sawn lumber is to save money in the long run. But in this case it was a matter of access to woods and the best source for this build was overpriced s4s poplar. Breaking down these boards starts with crosscutting to final length at my miter saw station.

Followed by ripping the pieces to their final width at the table saw.

While the design of this bookcase is very basic there are a few standard design elements in play. The lower face frame rail was sized to allow for the addition of baseboard moulding in the event that I wanted to add it in the future. At this time I do not. The lower rail is also the widest which will give it more of a stronger foundation appearance. The top rail is the next widest to allow for the addition of crown moulding in the event that I wanted to add it in the future as well. And again, at this time I do not want to add it. And finally the center rail is sized the same as the outer stiles just to tie the sides together.

Pocket hole screws are industry standard for cabinet face frames. Because the ugly appearance of the pocket holes is on the inside nobody will ever see them. And while pocket hole joints aren’t the strongest joint out there they are plenty strong enough for face frame construction. Never use pocket hole joints in situations where wood movement is necessary, like attaching a breadboard end to a table top. For more information about this pocket hole machine I have click here.

Clamping the outside stiles to the workbench makes quick work of assembly. The most annoying part is actually getting out of the way for the camera. Like this shot; I don’t think I would be standing behind the part to screw it together if the camera wasn’t recording :)

The good aspect of recording the build is that I can easily get a helping hand ;)

The back panel will be attached to the case via a rabbet in the side panels. In this case I made the rabbet about 2/3 the thickness of the sides and a little deeper than the thickness of the back panel. I have exact measurements in the plan but in this case I just eyeballed it.

This is the most important step of the build. I call it “screwing up the width of the fixed shelves and therefore needing to remove more material from the side panels to accommodate.” …..it happens.

Assembly of the fixed shelves is just as easy as the face frame. The lower shelf and middle shelf will have the pocket holes facing the ground and the upper shelf will have the pocket holes facing the ceiling. This means a 90 degree chunk of wood can be clamped to the sides to act as a stop block for each shelf. Then the shelf clamped to that chunk of wood. Once everything is secured with clamps the pocket hole screws can be driven home to lock the shelf in place. No fuss and no slipping with this method.

To attach the face frame to the case I laid the case on it’s back on my workbench. Coincidentally, I found out that the back panel needs to be the exact width of my workbench because it fit perfectly inside the back panel rabbets.

A little glue and a few brad nails will secure the face frame to the case. I used a couple of clamps to hold the face frame exactly where I wanted it before shooting the nails.

All of the nail holes get filled with wood putty.

For the four adjustable shelves to be adjustable I need to cut shelf pin holes. And to do that I’m using the JIG IT® Shelving Jig from Rockler. I bought this template back in 2008 when I first got into woodworking and have put a lot of miles on it. Rockler is a partner of mine and sent me another one to use. There is no need for me to open another one though so I’ll pass it along to someone else for free. Just leave a comment on this article and I’ll use a random number generator to select a winning comment 24 hours after this article goes live. EDIT: THANKS FOR THE LOVE ON THIS ONE. ANTHONY SCOLARO WAS THE RANDOMLY SELECTED WINNER.

The jig is simple to use. Line the jig edges up with reference edges in the project, the back and bottom in this case, and start drilling the holes as needed with the included drill bit.

Once you max out the travel of the jig simply use a shelf pin through the template and into a previously drilled hole and continue drilling as needed. Repeat this for as many holes as you’d like. Super easy and precise.

The back panel will eventually get attached with short screws. All I wanted to do here was make sure it was cut to the appropriate size before I started finish prep.

And finish prep consists of using a router to flush trim the face frame with the case sides…

Sanding all surfaces up to 180 grit..

And applying the finish. Just like everything else I’ve built for the office, this bookcase will be white with a few pieces of bubinga trim. On my cabinets and dog bed table I used Sherwin Williams white lacquer. The results are nice but man was it a huge pain in the butt to spray a solvent finish. The lacquer smells up my house for days, even when spraying outside because I store the project in my garage. And I can’t spray in my garage because the solvent smell is even worse in there. So for this project I tried out General Finishes water based white polyurethane primer and white polyurethane satin finish. Long term durability is something I can’t speak for right now but as far as the finished product goes, they both look and feel the same. The main difference is that I was able to spray the water based poly inside my shop and not worry about any of the crazy fumes. I wore a respirator (as you should always do) to protect my lungs from the dusty bounce-back and overspray.

Next up is the bubinga trim for the adjustable shelves. Earlier in the year I found a bunch of Bubinga being sold at $5.50 a board foot so I bought a bunch of it. That’s one of the reasons why I’ve been incorporating it here and there with my projects. For the solid wood banding on the adjustable shelves I started milling a chunk of 8/4 rift sawn material starting at the miter saw.

Followed by jointing two adjacent faces at the jointer..

And then getting the opposite faces flat and parallel with the planer..

Four pieces are ripped out of the board at the bandsaw. I should have had my fence rotated 90 degrees to allow for shorter cuts to be made with the blade guard dropped to the surface of the wood.

The bandsawn faces were cleaned up with a few passes at my drum sander.

And finally a rabbet is established with two passes at the table saw. There’s two things to notice with this picture. First is that the waste side of the cut is not being trapped between the blade and the fence. It’s on the opposite side of the blade so that it will sit freely once cut and not shoot back like a rocket. The second thing to notice is that my first cut was too deep. I’d love to say that this was on purpose to allow a little room for glue squeeze out but in fact it was because the insert plate on my table saw was set too low. I’m not sure what happened or how it got adjusted but because it was lower the beginning and end of my cuts here were too deep. I’ve since adjusted it but I’m still scratching my head as to how it was lowered.

Before gluing the bubinga onto the shelves I wanted to round over the corners. Whiteside Machine Company is also a partner of mine and for this task I’m using a Whiteside 2005C 1/8” radius round over bit.

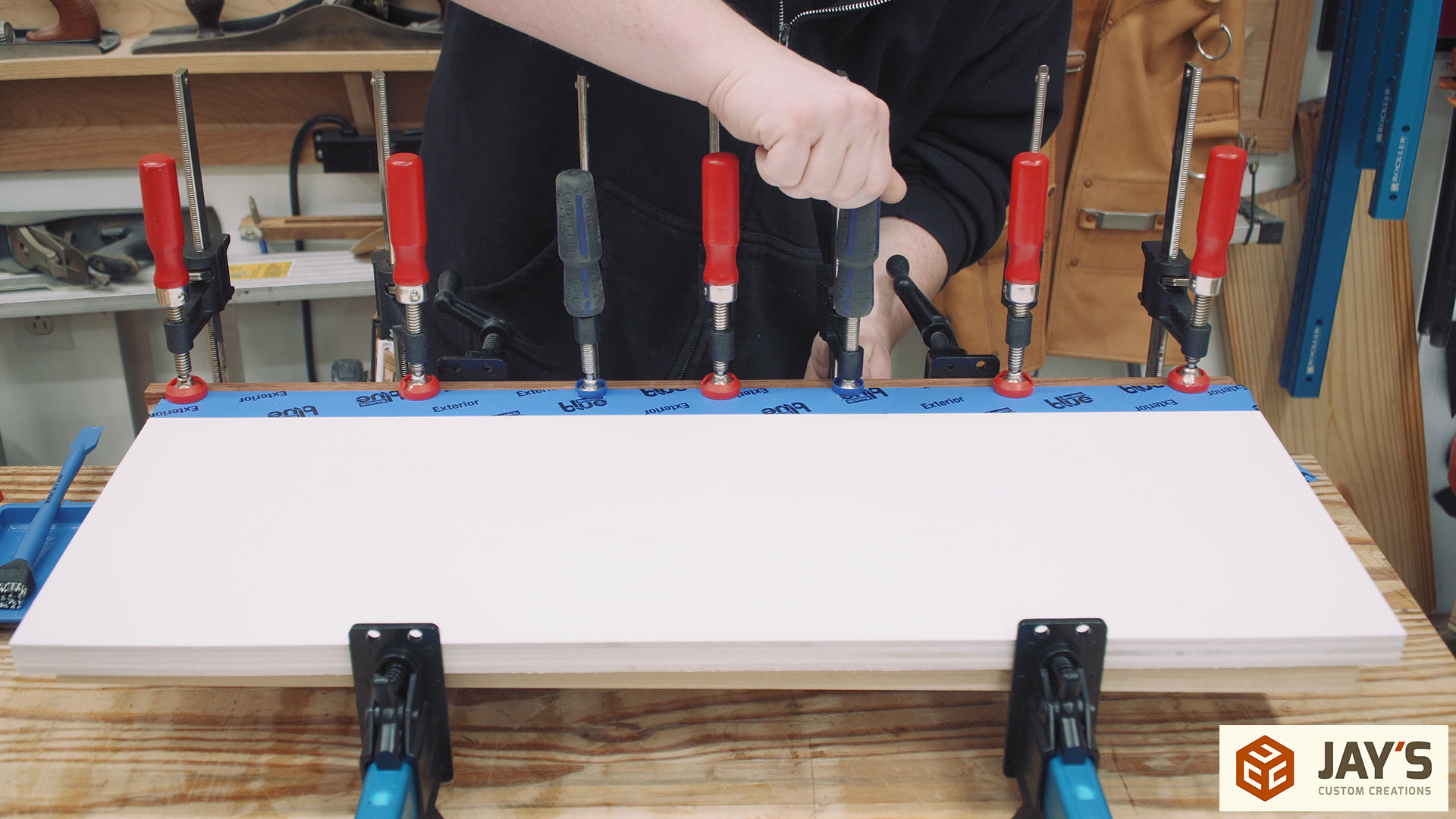

To prevent any ugly nail holes from showing on the solid wood banding I only used glue and clamps to attach them to the shelves.

Finally the back panel can be installed. I used a bunch of short screws to attach it. No glue is necessary for this piece.

By this time the solid wood banding can be trimmed down to the appropriate length on the shelves and to do that I used my crosscut/miter sled. I removed the insert plate here for better dust collection. The eight cuts that needed to be made were all pretty small and the offcuts were small enough to let them pass through the dust collection system.

A final sanding is needed on the bubinga. You can see how the small radius round over combined with the board being rift sawn allows the grain lines to blend all the way around the board. It results in a very even grain appearance regardless of what angle you are looking from.

To seal the bubinga I went with General Finishes High Performance satin water based polyurethane. And because it dries clear I went ahead and added another layer to the entire shelf. I figured that these shelves will see the most abuse on the project so one more layer of polyurethane will be nice long-term.

Add the shelf pins and this one is done! (kinda) I LOVE how much the bubinga stands out with the white polyurethane.

Here’s the “kinda” part I just mentioned. I forgot to record the process but in order for the bookcase to sit flush against the wall I cut out the profile of my office baseboard in the back bottom corners of the bookcase. I did this by making a template out of 1/4” plywood first and then transferring that shape to the bookcase with a flush trim router bit. I just went into the shop and got it done and forgot to record the process. Oops!

And here it is in use. Holding all of my shirts and hats that I sell here on this website. I finally have a place for them that is in the office instead of in a box in a room on the opposite side of the house.

Thanks again to Rockler for supporting this video. Stay tuned in the next month or so for the final before and after video of the office remodel. If you’re interested in a set of plans for this bookcase click here.

I love the camera work in your videos and that you show your mistakes and how you fixed them.

This is really a good looking book case. Thanks for sharing the build video.

Nice bookcase, inspiring video as well. Thanks Jay.

Awesome simple book shelf.

Beautiful craftsmanship, although the style really isn’t my cup of tea. Also I gotta point out that nobody has mastered this “social media/ content creator” platform better than you. You’re videos are clean and simple with detailed articles for more indebt look. The crispness and cleanliness of the editing is so good even somebody like me that knows nothing about that stuff can see it. Also the little Easter egg in the video to send folks to your site is just brilliant. Keep up the great work, because I’m enjoying the heck out of it.

Thanks for another great looking project. I am thinking about building one for my wife.

Awesome work as always Jay

Whoa!

Exactly what I’ve needed right now!

My now “ex-girlfriend” will get my office shelf…

And this rockler shelf pin template look pretty amazing!!

I love your passion here from Canada!

Thanks I’m really interested in trying the poly finish you used I didn’t see it on amazon, Where could I find it?

Contest entry

Really nice book case. Might try this project for little one’s four h project next year.

Have really enjoyed your videos and write ups, glad I came across you. This build is a great example of your work with good explanations as to how and why you do things.

Nicely done.

Did you get a new jointer/planer?

Some sort of convertible machine from jointer to planer?

I missed the discussion of that piece.

Looks like space saver.

Could you direct me to the discussion of that addition to your shop?

Thanks,

mt

Dat bubinga though

Nice simple bookcase. I really like it. Love the split frame where you have “extra” help in the shop!

Great work jay. Just getting into wood working and your content is fantastic and easy to follow

Nicely done. Like the contrast of materials.

I like the subtleness of your office furniture design with simple yet elegant pieces. I also didn’t notice you got a planer / jointer combo machine until this build. I’ve wanted one for a while but they aren’t cheap. Cheers.

Thanks for doing what you do. I wholly appreciate the step by step narration and methodical thought process that have helped inspire my early woodworking (mis)adventures! Thanks

nice build

I love your videos! You have inspired me to build some of the furniture for my new house. Thanks for the articles/ plans/ and ideas.

Thank you for another excellent video. You inspire me to get building in the shop.

I was just planning a bookcase for my first woodworking project. Love how simple and nice this one is!

Great project, well presented. I want the drill jig.

Man…I wish I had your equipment, and your skills haha.

Awesome video! Love the bookcase!

Nicely done. You have some nice new tools there. All the hard work is paying off. Merry Christmas to your entire family.

I’ve never heard of white poly before, but I’ll have to try it now.

Another great video. A bit surprised after your talking about dealing with the dog hair that you didn’t put some glass doors on it. :)

Love the contrast! I made an entertainment center with a similar color scheme. Thanks for the content Jay!

Nice. I really enjoyed reading the build after watching it. I’ll be making 3 of these in the near future myself. Congrats on the baby!

The Bookcase turned out nice and I love the camera work in all your videos.

Very nicely done. Do you have a rule of thumb for determining the width of the edge banding for the shelves with respect to the shelf thickness?

Beautiful bookcase, I love the way the bubinga adds a little flair. As for the jig-it shelf pin jig it is awesome. I have the shitter jig made by rockler and lining it up and drilling the holes couldn’t be easier

Thats supposed to be shutter jig, sorry. My phone strikes again

Nice build.

Love the way the shelves are inset inside the bookcase. Really gives it a different look and feel.

Cutting plywood on table saw gives me anxiety about kickback… any chance of a video going more into that? I’ve seen some but I still get anxious. I use circular saw but several times have measured wrong and cut was wrong! Grrr!

I am just commenting so I can win that shelf pin jig.

Jay, I really enjoy your YouTube videos and have followed you for a couple of years. Thanks for the great tips and techniques!

Cheers from Canada.

It’s always inspirational following your projects. I love the contrast in this bookshelf with the fronts of the shelves – it really makes the whole unit. Thanks for posting the videos and the articles.. keep up the good work!

Amazing bookcase! Going to make a smaller one next weekend!

Excellent bookcase. Here’s hoping I get the jig.

Great bookcase. I’ll definitely build at least one.

Great build. Always looking forward to your next video. Cant wait to hear about the new machine. I have been looking at removing joiner and planer and buying a combo to save space but always been afraid of losing quality or ease of use of separate machines that I know and and have no issues with.

Always fun to build a fairly simple project which is really useful. Thanks for the great video.

Great video, thanks!

Great easy design! I love the accent wood! I will probably end up making several of these for my mom’s quilting room when we move in the near future.

Love all your projects and learning a lot from your videos

Great bookcase

As always very simple and instructive, great!

Another great project Jay!

I like the contrast with the white finish and natural wood. Good work.

Love that contrast!

Thanks Jay.

Nice Build, Jay!

Thanks Jay. Glad to see I’m not the only one to have to “adjust” panels like that

I like the contrast between the white and bubinga.

Never really been a huge fan of ‘white’ on furniture, but having the natural wood accents really does help break up the sea of white. Excellent bookcase.

Love the look of that Bubinga in contrast with the white finish. Also peeping the new Jointer/planer!

Very cool build and looks amazing for the end result! Keep up the great work.

Great job, it looks amazing!

Great job on this bookshelf another inspiring video. Keep up the good work!

It’s nice how the simple projects can be made to look so much nicer with just a little accent like you did. Great work. I would also like to see a video about your new combo machine. That looks like it would be awesome to use.

Great looking shelf! Love the quality work.

Nice build!

Looks great, like most of your work. I’m not a big fan of white furniture, but you do you bro.

Very clean. Keep up the great work and great videos.

Nice simple build that works well.

I am just getting ready to build a couple of these for my office. Thanks for the video and article. Always enjoy your builds.

Something similar will be at the top of my list next year. Thanks for the vid.

Awesome contrast…never used Bubinga but I would love to on a project in place of oak…

Nice video Jay. Love all your great tools. Very nice build, and simple too, which is always good.

Nice set of shelves, always love the way you build and the way you edit your videos.

Looks great!

Man, that big would come in handy for our future diy cabinet pantry project. Good luck to everyone!!

Nice build! Thanks for the video, I learn something with every one you post.

+Great video, thank-you.

Nice project Jay, and great video as always.

Agree, the bright white and natural wood finish accent looks very nice.

As always a great video and article. Thanks for sharing your expertise with us.

Looking good.

nice shelf pin jig jay

I like the honesty of admitting your mistake when ripping the shelves and having to re-rip the case sides to account for the error. I try to instill a similar problem solving mentality in my high school woodworking classes. It is OK to make a mistake as long as you learn from it.

I always love the twin shots you put into the videos.

As always, good work, Congratulations.

I’ll be anxiously waiting for my tamplate here in Brazil :D kkkkkkk

.

Beautiful…I’m going to be stealing some of these ideas :)

The bookcase looks really nice. The contrasting bombings looks great.

Not bombings but bubinga is what I meant.

Not bombings but bubinga is what I meant.

Love the build, simple and clean!

Great info, I really enjoy your videos and projects

Yes Please!

(Are you from Michigan?)

I love ur channel, I’ve learn a lot from watching u build stuff I’m new to wood work but I have a couple of projects in mind like redoing my kitchen needs new cabinets I’m looking forward on taking on this project next summer. I’ve build mostly simple stuff like speaker boxes but I’m going into more complex projects, thanks for all the lessons. God bless

Great project. Love your channel!

Great looking simplistic book case.

really nice looking book case now my wife wants one

Wow that went together pretty fast, It looks good and sturdy.

Nice shelf. Sign me up for that jig please!! :-)

great video Jay. Thanks for sharing.

Great time for this build. Finishing up on a new desk and bookcases are next… sure could use a shelf pin jig!

I suppose you never really enjoyed playing Mortal Kombat seeing as how you don’t really enjoy the finishing process.

WOW, I just saw the Update that I won! I’m very grateful Jay and thanks for your generosity. This will make a great addition to my shop, looking forward to hearing from you. Let me know what info. you need from me.

Hey Anthony. I sent you an email. If you have not received it be sure to send one to me or send me a direct message on social media where you can send a shipping address.

I sent you the info on your instagram

I see new equipment in your shop, must be time for an updated tour!

Nice job Jay.

Nice. You have inspired me to no end. Next year I plan on starting a small business making bookcases that both people and cats can use.

Very nice!! Your projects always look very professional but still easy for us typical woodworkers to complete. The one question I have is regarding paint over spray. It would appear you are in a closed area (garage??) and the over spray has to go someplace?? I also am limited to a two car garage and have wondered before about the ease of spraying inside.

Thanks for your years of vids and helpful projects.

Looks great. Love Rockler equipment, but a little out of my price range. I enjoy your videos. Keep up the good work.