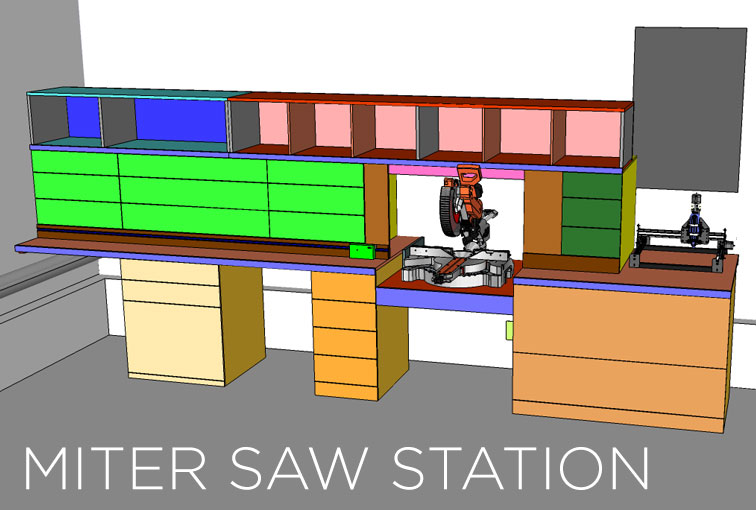

I’m FINALLY getting around to making my dream miter saw station. I’ve been putting this project off for a while for two reasons. I wanted to make sure that this was the final design I would settle on. Sometimes letting completed designs sit in the back of your head really forces you to think bout all the details to verify that is what you want. And the other reason was the cost. It’s a pretty decent size and due to the amount of drawers I am incorporating the material list got a little crazy.

I have a detailed set of plans for the entire completed miter saw station at the bottom of this post.

There’s simply no way I can fit a project this size into one video and article. It’s just not going to happen so I’m breaking it into three build phases. This first phase will cover the cabinet frames and the work surface. While this is technically the first phase of the build it is actually the second attempt at the first phase because of a recent Chinese plywood disaster. I really feel like I need to shine a light on the issues about disappointing and possibly unsafe Chinese plywood so if you haven’t already check out my recent post regarding it. Due to that experience I reached out to the folks at PureBond to see if they would be interested in sponsoring this build. They gladly accepted and really saved the day on this build. If you aren’t familiar with PureBond hardwood plywood it is made in the USA and Canada, formaldehyde free, and available exclusively at The Home Depot.

The nearest Home Depot to my house is about an hour and fifteen minutes away but it was worth the drive. This plywood is night and day better than the crap I used the first time around. My design called for 12 sheets of 3/4” plywood and that’s pretty much the limit of my small truck.

With the help of my infeed support arms and an outfeed table I was able to cut all of the pieces with relative ease. This is the first shop setup I’ve had where I could comfortably break down full sheet goods on a table saw. Previously I would use a homemade guide track for my circular saw and make the first couple cuts with it.

After everything was ripped I crosscut the pieces to length at my miter saw table. I’m soooooo glad this is the last time I will be using this miter saw card table setup.

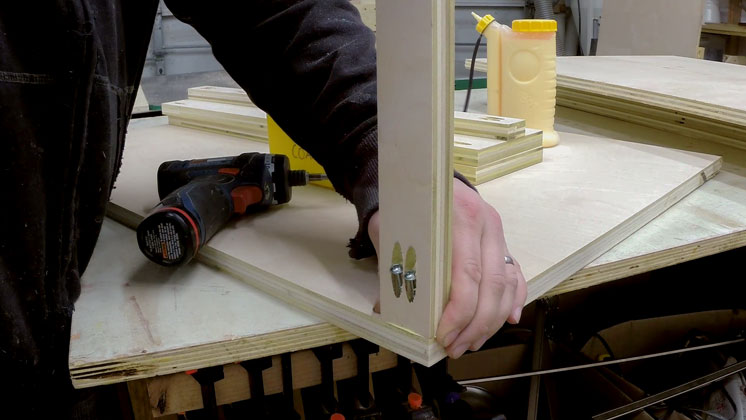

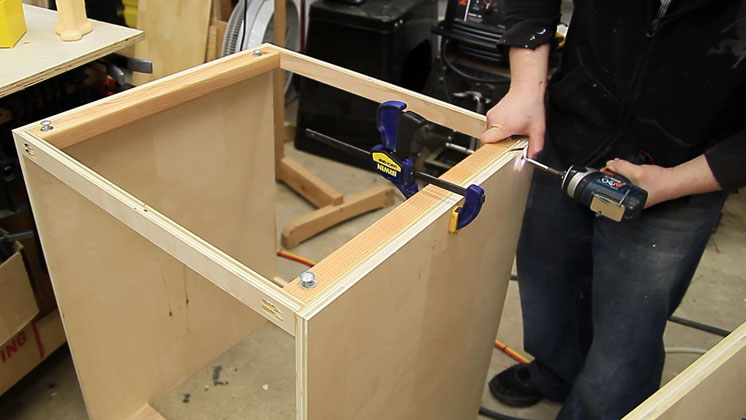

The vast majority of cabinets these days are constructed with pocket holes. It’s a quick and easy way to produce a joint that is plenty strong enough for this application. Any pocket hole jig will work. I had 168 pocket holes just in this phase of the build. There will be a ton more next week when I tackle the 20 or so drawers.

Assembly is pretty straight forward. Two same width pieces on the bottom front and back and two same width pieces on the top front and back to join the two panels.

I secured all of the horizontal strips to one side first. Then I laid other side panel on top and secured it. Because these will be sitting in place and secured to the bottom of the work surface no more bracing is really needed.

You may see the quality of images change a bit in this build. I used my GoPro camera for most of it and I haven’t quite figured out the color balance just yet. With the lower cases built I made some leveling feet from strips of 2×4, tee nuts, and galvanized carriage bolts. I went with galvanized carriage bolts because the corner of my garage where the left side of this miter saw station will be occasionally floods slightly when it rains heavily outside.

I measured and placed the lower cabinets where they will be in relation to the walls and leveled them starting with the middle cabinet. I though this process would really take a while but it was actually not a lot of work at all. Just start with the highest corner of the highest box and make everything match it.

Here you can see why I didn’t make my cabinets go all the way back to the wall. The base cabinets are 24” deep and the front edge is at 36” away from the wall. This gives me future access to my dust collection plumbing as well as all of the electrical on that wall. With the cabinets level I used a straight edge to transfer their height to the wall where I mounted a strip of pine 2×2.

That 2×2 also extended around the corner along the far wall. From there the top surface is mounted. I used screws through the plywood into the 2×2 and through the tops of the cabinets and into the plywood work surface.

The left section of the miter saw station is a full 8′ long. The right section is a full 4′ long. The miter saw section in between is about 2” wider than the minimum distance to accommodate my miter saw. With the appropriate height measurement marked I used a couple of pieces of 3/4” ply to create a ledge for the miter saw shelf to rest on.

With that shelf resting in place I could use its position to locate the right section of the miter saw station.

And the top is mounted the same way.

I’m not going too crazy with the dust collection. My objective is to create a draft that will draw all of the dusty air away from me and into the dust collector. There will be a lot of space in the dust collection area for the larger sawdust to fall down. If it doesn’t make it directly into the dust collection port I am totally cool with brushing the larger dust into the port once or twice per year. I’ve used this exact setup previously with great results. I’m using half of an old harbor freight blast gate as a dust port.

To hook it up to the dust collection pipe I used one of my blast gates and some flexible hose. I’ll extend the blast gate arm at a later date. Until I do I’ll just leave it open. Space was a little crammed under there so I had to use my head to lift up the panel to attach it all.

Finally that panel can be secured. I thought it was wise to only use two screws per side to hold it in place to allow for easier removal if the need to ever arose.

There was a resulting gap behind the miter saw where the shelf met the back side of the cabinets. I used of ply to cover these areas. I cut a small notch in the left side panel to allow for the cord to pass through.

Because my miter saw is so large the area required for proper movement of the back arm is quite large as well. It’s actually quite a bit of dead space. To keep the air flow more centralized with the miter saw I added two wings to both sides of the saw area.

The last addition to this phase is the fence board. This ties all of the cabinets together and is where I will mount some T-Track at a later date for a stop block setup.

Like I said this is just the first phase of this build. It’s a rather in-depth build to try to cram into one video and article. Next up will be the drawers……lots, and lots of drawers. I have a detailed set of plans available for those who are interested.

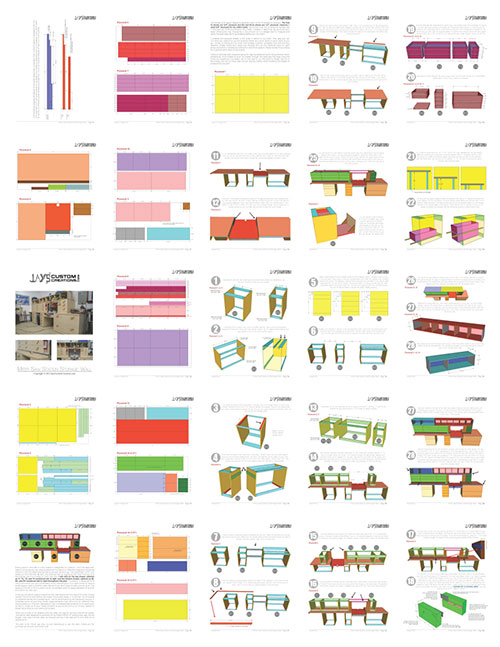

Miter Saw Station Plans:

Ultimate Miter Saw Station PLAN

$19.99

Description

This miter saw station has been an incredible increase of shop organization and greatly increased the ease of use and dust collection for my miter saw. It is 177″ long, 37″ deep, and about 71″ tall depending on the leg levelers. It features 21 drawers of various sizes, a slide out tray for storing a benchtop planer, and a row of quick access tool bins at eye level. The empty space on the bottom left houses my air compressor. The next empty space in the bottom houses my trash can. And the open work surface to the far right houses my small CNC machine. A drill press would work well in this location. The plan is in imperial units only but you can change the SketchUp file to read metric units if you prefer. A link to the SketchUp files I used to create the plan are included in the plan. I broke the project into four parts and made a build video and article on each:

- Part 1 – Carcasses and work surface

- Part 2 – Drawers and drawer installation

- Part 3 – Drawer fronts and shelf boxes

- Part 4 – Stop block system

Included in the miter saw station plan:

- 28 detailed pages

- shopping list

- plywood layout diagrams

- reference diagrams for specific part dimensions

- step by step 3D assembly diagrams with written instructions

Here is a follow up video close to two years after making it that covers a lot of common questions:

Here is a follow up video close to two years after making it that covers a lot of common questions:

The entire plan is included in one PDF document. Most everyone will have a PDF reader installed on their computer already but if you do not you can use the free program Adobe Reader to view the plans. You can download Adobe Reader HERE. The checkout process for this plan uses PayPal. You can use major credit or debit cards through PayPal. You do not need a PayPal account. To purchase the plan follow the link below. After you purchase the plan you will receive an email receipt from me containing a link to download your plan. Make sure to check your inbox and spam filter for the receipt. If you do not receive the email within 10-15 minutes or encounter any problems please contact me.

Awesome build looks good !!!!

Thanks

Nice design for the miter saw station. I’m envious of all that room that you have to work in!

I know the feeling Jay about finally getting to a project that you have been wanting to do for a long time. Really taking shape. Gonna be a great build. Looking froward to “Part Deux” !

Thanks Dorald. I’ve been putting this one off for too long.

You really get in to your work in some the pictures, awesome looking build. Looks like I’ll need to get a few more shirts

I understand that it will be multifunctional – but that has got to be the largest miter saw station I’ve seen. My miter saw seems to be an orphan tool – no real home. It gets pulled out and put back when I need it (what a pain). Very nice – can’t wait to see the end product.

It’s 14.5′ long. The first objective was to create a storage wall. The second was to have a miter saw station.

PRECISELY the design goals I had for mine. I haven’t done my doors or drawers yet, but the design is REMARKABLY similar. But I’m in what realtors call a 1 car garage that isn’t big enough for my truck or my wife’s car, so I was only able to make the base cabinets 18″ deep, and I only had an 8’x8′ wall area for the whole thing (but I have 8′ of room out from the blade in each direction for long boards). And I’m fortunate enough to have a brother-in-law who runs a cabinet shop so he ran all the boxes on his industrial CNC. The entire cutting process, including dados and stretchers and nailers and shelf pin holes and shelves and everything but the doors and drawers was done in 1 hour. Another 20 minutes to edge band all of it on his machine the size of my truck. I felt like I was “cheating” but it got the job done and I don’t know when I could have done it otherwise.

I’m still using a cheap craigslist 12″ Ryobi non-sliding miter saw for now, but I designed the thing to hold a Bosch gliding saw. Just waiting for them to go on sale again, probably for Father’s Day. But even with my cheap saw that has to be checked for square a couple times a week, and without any usable drawer space yet, it’s still a dream compared to the tiny table I was using before. Everyone should have a solution like this, with tool and parts organization as well as a cut station. The specific design will vary, but having the storage spots gives you the ability to have a system for organizing your junk.

OMG, you used the dreaded “pocket hole” construction. lol. Great job, wish I had the room for that station. I had to put mine on wheels with flip up wings.

Pocket holes complete the task just fine.

Great looking miter station. I cant wait to see the finished project. keep up the good work.

Thanks Lancer. I appreciate it.

I think the miter saw has some of the crappiest dust collection. Problem solved and storage quadrupled! Awesome project.

Thanks Ty. This will definitely be leaps and bounds better dust collection than it currently has. I used this same setup in my last shop with great results.

Jay

Once again you have created a very useful and creative work station .

Your videos are very educational and very entertaining ( love the double speed and sound effects).

Keep up the great work and GOD bless your hands and mind.

Gregg

Thank you very much for the feedback. I appreciate it.

Awesome!

very nice build Jay , you gave me some great ideas for my station

Nice, simple project. Well done. Thanks for video. Another well spend minutes watching your work.

Just wondering, is the shelf holding the saw just 3/4 plywood or are there other supports for it. Guess I’m wondering what weight will cause sag.

Rod

The design calls for supports below. I haven’t gotten to that point yet.

See you got the hair cut you were talking about, now you just need to take a few steps closer to that razor when you shave.

That miter saw station is a monster, can’t wait to see it done.

Looks great so far. I do have a question tho…..It’s regarding the wings you attached to the top cabinets to help contain the dust. I don’t see a problem on the left side, but if your saw also tilts 45 degrees to the right, will that right wing get in the way of the handle when you make a cut? It’s tough to tell from the picture, but it looks like it’ll be close.

Just a thought….

It won’t hit. I took that into consideration when designing it.

Jay, as always your new project is coming out really nice. Are you planning on putting that CNC machine in a pull-out drawer? or will that be its permanent home? As always looking forward to your next video.

Thanks, and again Great Job.

Hey, Jay, great looking progress so far. I saw this and the video and was trying to figure out why you did it but I couldn’t. Why were you driving the pocket screws in then backing them out and then back in again? Is it to combat the mushrooming in between the joints? Would love to know this reason behind this Jedi trick.

Looking forward to more!

Brad

My 12v drill isn’t strong enough to drive the screw in in one motion. It always shifts the joint. My 18v drill has no problems.

WOW BEAUTIFUL! Sure beats the hel out of mine.

Love the projects and your style. BTW, the Subway Ad on the page started autoplay and I had to scroll down to pause it so I did not have multiple audio feeds playing.

Thank you for your feedback. That’s not supposed to happen. I apologize for the inconvenience.

Wow! I’m amazed you did all of that in 8 minutes. Looks good.

Looking great man. How did you plan your cut layout for the ply? I’ve never had good results using the sketchup cutlist plugin, do you use that one or something similar? I’m currently writing a cutlist style program myself as I’m sick of wasting material (and money!) by not making the most of what I have.

The cutlist plugin sucks. I manually copy my model and dissemble it on top of rectangle the same size as the plywood.

yep been there, i’ve found pen & paper is the easiest way for me, though probably not for a project with so many cuts like this one. Hopefully by Wednesday week I’ll have something that is consistently better than a person at laying out panels.

Jay, that’s another well-thought-out project, well executed. It’s a good adaptation of a storage wall to be a miter saw station, with very little compromise in either part.

Thank you very much. I appreciate it.

Is that 600.00 dollars of plywood already used or is there more to come?

Much more to come. No way I can fit it all in one or two videos. Next up is the drawers and some bracing here and there. This phase of the build only used 5 of the 12 sheets of 3/4 ply

This is probably a boob question, but I have found it incredibly difficult to get pocket hole joints to align perfectly. Even with a Kreg pocket hole clamp I find that as soon as I start screwing in the pocket hole screw, the pieces become unaligned and I end up with a crap joint. Am I just being inept? Is there a secret?

Sorry… nob question! DOH!

WHAT??? NOOB! Curse you keyboard!

hahaha…I understand. The boards are not clamped tight enough. If the boards are clamped tight it won’t go anywhere.

Hi Jay Are you making leveling legs out of carriage bolts and T nuts ? Do they work out well I am thinking of doing that on Kitchen cabinets in my VERY unlevel basement floor. Great build by the way I think it will be a jem when you get done.

Thanks Dennis. Yes, carriage bolts and tee nuts. They work great! And much cheaper too.

Is that the 10″ or 12″ ridgid miter saw? How do u like it? I’m thinking about getting the 10″ slider.

Sorry, forgot to add, is the saw accurate enough to make picture frames? Is the 45 degree notch truly 45??

Looking good Jay!!!!

Just a thought . . . with the cabinets covering the wall, now would be a good time to add electrical outlets, etc. The holes cut into the drywall would be covered by the base cabinets.

Hey Steve. I designed the base structure to fit around the existing electrical outlets that I have.

Nice build Jay. How do you like the Ridgid miter saw, is it the 12″ model? Thanks

Yes it’s the 12″ model. Zero complaints.

Jay, what are the side to side measurements on your miter station where the saw sits and distance to table. I just picked up the 12″ ridgid like yours while Home depot still had them. Looking to build a mobile station like Aprils. I think you said you had to change the measurement to get full side to side miter adjustments.Thanks Jay

The recessed saw platform is 33″ wide. The fence needs to be about 27-1/2″ away from the wall.

Thanks Jay

Thank you!

Very nice build ! I have a portable miter saw witch gives me zero storage around it. Do you have any plans or specs available? I would like to build something like that for my garage woodshop.

Awesome build Jay! Was this PureBond 3/4″ Birch plywood??

Yes

I am so impressed. You make it look so easy. Your Kreg set up is fantastic. WELL Done.

Great station. I’ve watched a few of your videos and after it asks if you want plan. I’d love the plans, but I’m unable to find them.

I’d like the plans to the station and the drawers.

Thanks Rob. I’m actually working on the plans at this exact moment. I should have them done tonight and will post them either late tonight or early in the morning.

Very cool design and looks sweeeeeet! going to build similar system for my back wall and fit 2 roll around tool boxes into it!

hi Jay, how does the dust collection work ( probably you answered before ). can you show some pictures ?

I have a DeWalt miter saw that throws the dust upward, but I wan to change this backward. thanks.

btw, great design your station ;-)

I’m about to shoot tomorrows vlog video. I’ll show it in the video.

Hi Jay

Love your videos and ideas, they break down the hard stuff into easy to follow guides. I’m new to the woodworking scene, got the bug for it 18 months ago and have a nice collection of tools for an amateur. I have a question for you. I’m in the middle of a small shed makeover, and have built two cabinets for my chop saw station which will be similar to yours. I drew a level line on the wall for a reference point. I was able to spend some time tonight putting on t- nuts and bolts to get it the cabs level. My floor has about a 40 mm slope from right to left. My plan is to start at the high point and work my way to the other side. My question is where do I start at the levelling process, do I get them level along the wall and the from the wall out or visa versa.

Thanks

Kyle from Dublin Ireland

If you already have a level line on the wall then it doesn’t really matter where you start with the cabinets as they all have the same destination height.

I would also take a level from the wall into the floor, is that level too ? Then I would build one single “throw away” frame setup for the entire base, so that you know your levels for the area, not just along the wall. Similar to the way concreters’ build boxing for concreting. Then build the cabinets inside this frame, checking levels against it constantly. Your cabinets will then sit to ground and you can remove the frame.

Great job, Just what i was looking for

Hi Jay, what sort of compound sliding mitre saw do you have? have you ever done a video about what to look for in a saw like that?

I have watched this build a few times now… killer job. One question – where did you order your tape measure you stuck down to it from please ? I am about to do this same build down here in New Zealand, looking forward to it !

That’s my dream too :)