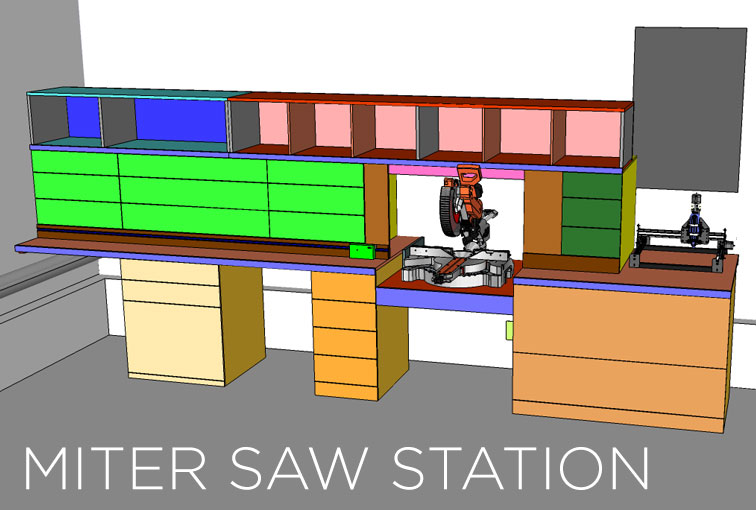

Drawers! Drawers! Drawers! I love using drawers for storage. I mentioned in my end of 2013 shop tour in my last shop that if I were to start over with a new shop I would use drawers every chance I could instead of cabinets with doors. Here we are a year and three months later and I’m doing just that. My miter saw station/storage wall build will incorporate 20 drawers and one slide out shelf giving me a ton of storage to get organized and hopefully more productive.

I have a detailed set of plans for this completed miter saw station available at the bottom of this post.

My recent cheap Chinese plywood nightmare really opened my eyes to disappointing and possibly unsafe Chinese plywood and because of that I’m using PureBond birch hardwood plywood for this build. This entire miter saw station is sponsored by PureBond hardwood plywood which is an absolutely perfect fit for me. If you aren’t familiar with PureBond it’s a non toxic, soy based plywood made in the USA and Canada. And because it utilizes a soy-based technology it is a much safer alternative to toxic, formaldehyde-based resins. It’s available exclusively at the Home Depot. After completing this phase of the build and having cut up 11 full sheets so far I’m so glad to be working with it.

In the first phase of this miter saw station build I constructed all of the cabinet carcasses and the saw work surface. The first step in the drawer phase was to mount all 3.75 million of the drawer slides. Technically, I used 23 pairs of slides but man did it feel like a lot more than that. Luckily installing them isn’t too difficult. The easiest thing you can do is cut a few spacer blocks to easily locate all of the slides without measuring. Just use the blocks to locate the slide and secure it with the included screws. I tried to change things up a bit and was going for a cinematic feel in the video which is the reason why these images may look a little different than my typical images. Let me know your thoughts on that aspect as well!

Working my way down from the top the process is incredibly smooth. The drawer slides I am using are from Outwater Plastics. They have the best prices I’ve found on full extension slides. If you know of cheaper prices let us know in the comments below!

And here they are all installed and extended. I extended every one just for pictures and then immediately put them back. It wouldn’t be long with them sticking out until I would somehow accidentally bend one of them.

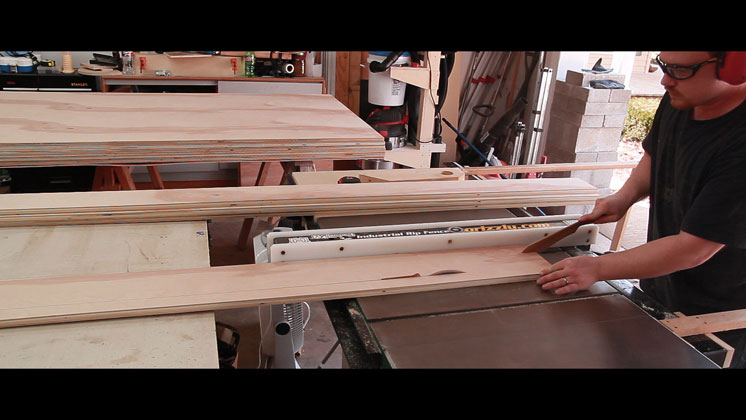

This project was a great learning experience for perfecting a technique to cut full size sheet goods on my table saw. I didn’t use my circular saw at all in this project which is a first when working with full size sheet goods. I couldn’t have done this without my super easy infeed support arms. They really make this process a lot safer and easier on me.

I wanted to rip as much of the plywood along the long direction as possible. It’s just much easier to only have to worry about plywood that is 48” to the left of the fence instead of ripping along the short direction. So that meant a lot of long strips made on the table saw.

The miter saw station isn’t complete yet but that doesn’t mean I can’t use it to finish the job. Clamping a speed square to the work surface makes a great stop block for repeatable cuts. Once complete I’ll incorporate a t-track and stop block system to the left of the blade.

Joinery is a hot topic with woodworkers these days. I’m more of a function over fashion kinda guy and because I’ve never in my life had a pocket hole joint fail on me that’s the route I went. It’s really hard to beat the production speed of using them. Especially with my Foreman. Unfortunately I did break the drill bit with about 25% of the pocket holes still to go. I used my K4 to finish the pocket holes.

After cutting all the pocket holes for the drawer pieces I turned my attention to the drawer bottoms. This is one area I simply could not get around ripping along the short direction of the plywood. To make the process a little easier and safer I secured some wood to one of my I-Beam sawhorses at the same level as the table saw. This would carry the weight of the plywood and all I had to do was make sure to feed it correctly through the saw.

I did have a few panels that were about 24” wide and 96” long. Those measurements aren’t too safe to crosscut on the table saw so I used the miter saw. With a stop block setup I can cut, flip the board, and cut again to easily crosscut to a repeatable length. I believe I can get a full 26” or 27” crosscut on this miter saw by using this method.

Finally all the pieces were cut and assembly could begin.

I use glue on all of my pocket hole joints.

Standard pocket hole construction. I use the pocket holes in the front and back pieces of the drawer with the pocket holes facing the outside. That way there are no pocket holes on the inside of the drawers. The pocket holes on the front of the drawer will be covered by the drawer front and the pocket holes on the back of the drawer will only be seen if the drawer is completely removed and turned around.

For drawer bottoms I used 3/4” plywood secured directly to the bottom of the box with glue, a couple brads to hold its position, and a bunch of 2” wood screws. Attaching them to the drawer slides is super easy. I picked up this method from John Heisz. Use spacers to position the drawer exactly where you want it inside the cabinet and insert the drawer.

Then pull out the drawer and drawer slides just enough to get screws in the first holes on the slides. Continue the process until you have the entire slide attached to the drawer and remove the spacer blocks.

Then another spacer can be added to the top of the first drawer and the entire process is repeated. It’s quite easily actually.

After a long days work of building and installing I had a very rewarding sight. Lots of drawer storage!! So exciting :)

The bottom right cabinet is the largest in this miter saw station and also has the least amount of drawers. The drawers themselves are just shy of 48” long, 24” front to back, and 10” deep. This is where I’ll put larger items like boxes of paper towels and stuff that isn’t used often like my benchtop 8” grinder. The original design was to use four shallower drawers here but I changed my mind to two deeper drawers at the last-minute which was after I had ordered the drawer slides. This meant I had two extra pair of slides. Rather than let them collect dust until I found a use for them I chose to double up the slides on these drawers. So now each of these drawers can theoretically support 340 pounds. I’m up to 200 pounds these days and it held my weight just fine.

In the bottom left cabinet I made a pull out shelf specifically to store my planer out of the way. This is another feature I’m really glad I incorporated into the build. Every other drawer slide in this build is 24” long. The slides on this shelf are 26” slides to give a little more elbow room when picking up the planer.

So that wraps up phase two of this build. Next will be some divider storage above the top drawers. I also have a detailed set of plans available for those who are interested.

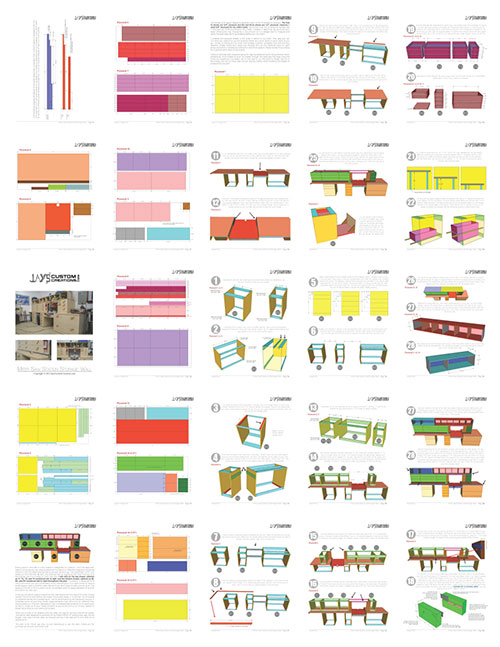

Miter Saw Station Plans:

Ultimate Miter Saw Station PLAN

$19.99

Description

This miter saw station has been an incredible increase of shop organization and greatly increased the ease of use and dust collection for my miter saw. It is 177″ long, 37″ deep, and about 71″ tall depending on the leg levelers. It features 21 drawers of various sizes, a slide out tray for storing a benchtop planer, and a row of quick access tool bins at eye level. The empty space on the bottom left houses my air compressor. The next empty space in the bottom houses my trash can. And the open work surface to the far right houses my small CNC machine. A drill press would work well in this location. The plan is in imperial units only but you can change the SketchUp file to read metric units if you prefer. A link to the SketchUp files I used to create the plan are included in the plan. I broke the project into four parts and made a build video and article on each:

- Part 1 – Carcasses and work surface

- Part 2 – Drawers and drawer installation

- Part 3 – Drawer fronts and shelf boxes

- Part 4 – Stop block system

Included in the miter saw station plan:

- 28 detailed pages

- shopping list

- plywood layout diagrams

- reference diagrams for specific part dimensions

- step by step 3D assembly diagrams with written instructions

Here is a follow up video close to two years after making it that covers a lot of common questions:

Here is a follow up video close to two years after making it that covers a lot of common questions:

The entire plan is included in one PDF document. Most everyone will have a PDF reader installed on their computer already but if you do not you can use the free program Adobe Reader to view the plans. You can download Adobe Reader HERE. The checkout process for this plan uses PayPal. You can use major credit or debit cards through PayPal. You do not need a PayPal account. To purchase the plan follow the link below. After you purchase the plan you will receive an email receipt from me containing a link to download your plan. Make sure to check your inbox and spam filter for the receipt. If you do not receive the email within 10-15 minutes or encounter any problems please contact me.

Wow! Your writeups are starting to match the thoroughness of Matthias! I like that your photos are pulled straight from the video to pull it and the writeup together. The only thing I would suggest is a way to enlarge the photos in order to see more detail. But I suppose that could be saved for a step by step build instruction to go along with the plans.

Hey David. Thanks for the kind words. I thought about adding larger images that only display when clicked but wasn’t sure if it would be worth the effort. Thanks for the thoughts on it and I’ll look into it again.

Great work Jay… think you’ll have to build a Library step or something to get to the top draws!

Hey Bob. I’m only 5’6″ tall and every one of the top drawers will pull out below my chin so I can see inside them. I took a lot of time to plan the height of everything for that very reason.

Great video as always. Did you consider mounting the thickness planer in one of the top cabinets rotated through 90 degrees? That way you could pull it out use it and put it back without having to lift it every time. You could even use an adjacent drawer / shelf to catch the materials and maybe have it connected to the extraction for the saw.

I thought about that but in the end didn’t want to get too complicated with it. At this rate I use my planer two or three times per year so lifting it out to use isn’t that big of a deal.

Drawers, drawers and more drawers. I too am a drawer freak, and now I’m jealous. You suck :)

It happens :)

Looking very good Very professional work. I have been needing one of these stations for a long time myself and you have inspired me to get started with it

Thank you very much for the feedback Mark. I appreciate it. Good luck with yours!

Jay, I am more of a metal working guy. I’m reaching my 50’s and never had any affection for woodworking. I started looking at some videos on Youtube about jigs, then you , john and the other woodworkers popped up as suggestions and, I have to say you all gave me the ITCHIES about it… I got to realize that with some basic tools, I could probably give it a shot. IT WORKED!! Now I’m hooked (Thanks to you guys). This spring, if it ever comes (I’m in Quebec Canada with 6 feet of snow on the front lawn…) I will be Overhauling my tiny shop (19 x 6). This project has given me so many ideas, I thank you for it! Will post before and after pictures as I am no video artist.

Thank you Jay for being a part of the inspiration I needed.

Dan

That’s very awesome to hear Dan. Good luck with your shop renovation!

Wow… you are crazy ! :)

Thanks! :)

Thank you for getting in one, when I saw you step in one I thought, well he has to lay down, he just has to so he can know for sure or not.

Now we all know and can move on with our days secure in that knowledge.

hahahaha That’s funny. I couldn’t resist.

If I had to build and install that many drawers in one day, I would be building one for a place to take a nap too! Love it :-)

lol. I slept good that night.

I bought a sheet of the PureBond Plywood, I would have to agree it is a great product, where did you get your drawer slides, when will you have plans to download.

Hopefully I’ll have a full set of plans within two or three weeks. I’ve got a ton of stuff going on right now. The link to the drawer slides is in the article near the first drawer slide pictures.

Again #AWESOME (enough said)

Thank you very much Courtney!

Amazing build. Keep up the great work.

Thank you Lancer. I very much appreciate it.

That is a *TON* of storage, nicely done (as usual)!! Bonus: It doubles as a “Panic Room” for the coming zombie-apocalypse – they’ll never find you in there!

It was a little crammed in there. I think I would freak out if left for more than a couple minutes without stretching!

Great job and well deserved rest at the end!

Thanks Rich. I appreciate it.

You will e-mail us when we can BUY THE PLANS-right!

I’ll email everyone on the list letting them know the plans are available once they are complete.

Great build, this one gets number 1 of Jayscustomcreations best builds every

Thank you very much for the kind words Gary.

Hey Jay, can u comment on rules of thumb for sizing of drawer vs opening and vertical spacing between drawers? Also i am considering hardwood sliders instead of linear glides… Thoughts? I am making a much smaller scale mitre saw station and am a little bit blurry on those details. Looks like a great addition to the shop.

Thanks for the video Jay.

Metal slides vs wood runners are personal preference. I’ve made purely wooden runners before and they work OK. I just prefer the metal slides. I size the drawer to maximize as much space as possible while keeping 1/2″ between the top of one drawer and the bottom of another.

i REALLY ENJOYED WATCHING THIS BUILD JAY , I NEVER WOULD HAVE THOUGHT OF A DBL ROLLER ON ONE DRAWER–VERY SMART

THANKS FOR SHARING

Thanks Nino.

Hi Jay,Great video as usual.Is your wife getting you the sheets and pillows for your “foldaway bed” ?

lol. I can’t sit in there long. It’s too crammed.

Not sure what was funnier, you sleeping in the drawer or seeing an ad for Fruit of the Loom underwear in your picture tutorial!

Where did you get that glue applicator? I see that Steve Ramsey uses it as well.

It’s from FastCap.

hola Jay Bates, me gusta mucho tu canal eres muy bueno y me ha ayudado mucho tus projectos, espero entiendas mi comentario, hay una cumunidad latina siguiendote, yo hablo por ellos un saludo y esperamos ver mas videos de tus proyectos muchas gracias

Hi jay,

thoroughly enjoyed both the build and your video techniques, I take it you used abetter quality plywood this time, after you last mishap??. Thanks for sharing, I look forward to your posts and save them all for future viewing, and reference,

Cheers from the UK

Dave

I’ve been waiting for the mitre saw station videos because I need one in a BAD way.

Mine will be about 1/4 this size though.

Thanks for giving me inspiration.

I’ve heard people coming out of the closet, but your the first coming out of a drawer. Great job, enjoy your confidence. Lookin forward to the drawer fronts.

Inspiring and entertaining. I love the projects that you share with us and that there is always something funny in them, whether it’s watching paint dry or you coming out of a drawer. I always look forward to your new videos. :-)

Jay, nice job! Some good ideas for sure. I especially liked your technique for cross-cutting the wide board on your sliding miter saw. I have a similar saw and I never thought to just flip the board over to cross-cut boards in the 13-26″ range. Thanks for the tip!

Good Job Jay – This type of build is why we all watch, you always come up with a solution to problems we all have in the shop. I just wish I had as much shop time as you do, must be rewarding to do what you like for a living, Thanks for checking into my email registration problem.

Loved the video and the photos as well. Can I ask how much did it cost in total to do this project. Material and all?

As always thank you for taking the time to share.

Jay, awesome build, I am really loving this thing! And I’m continually impressed by your eye for figuring things out and using simple and effective techniques. TYour usage of the spacer blocks made the whole thing look so simple. Bravo!

Brad

You never fail to impress Jay…love your work…hate your guts…I have like one drawer in my pathetic little shop and you have so many you take naps in them? What a show off! Beautiful work though, I’m truly inspired.

Jay, very awesome video. You are an inspiration to all of us wanna-be’s. Thank you for being …..you. I really appreciate watching your wonderful videos. I especially appreciate your promotion of pocket hole joinery(Kreg Jig)as that is what got me re-interested in woodworking as i approach those retirement years. Just a quick question: of all the stuff I saw in your video just now I was intrigued to know what was the brand of tape measure that you prefer to use?

FastCap lefty/righty tape measure

another nice post!

how many time it take? days, weeks?

my miter saw station really need to be improved

Nice work Jay! A pillow would make a nice addition to the large drawer. You can take a nap and then wake up and get to work in shop. Now all you need is a shop fridge and you’re set! I love the way the station is coming along. I may have to build one myself in my new shop.

Thanks for the drawer slide link Jay,

Is the plywood actually 3/4″? If not, did you adjust the depth for the pocket holes. I have had several screws pop the surface when I haven’t adjusted.

GREAT GREAT GREAT job Jay. It is by far the best “non verbal” video on the Tube. There have been so many tips and tricks on the two build videos. Thanks again.

Will you use the same plywood for the drawer fronts as well?

Yes. Just pre-finished on panel for it.

Great video. I learn four skill from your video. First, drilling an extra pocket hole for the clamp. Second, cutting wide boards on the miter saw. Third, sliding in the drawer, with drawer slides mounted on the case (testing the fit) and fourth mounting the drawer slides to the drawer. Thanks.

Jay, was there identification markings on the Purebond plywood edges that you purchased?

I have read complaints on woodworking websites that some of the Home Depots have been notorious for selling cheap Chinese plywood that often delaminates or has large voids exposed when sheets are cut.

Dan

Jay, you continue to improve and impress me. Your sense of humor just pops out at times! I appreciate how you show important parts in detail, and then go into mad rabbit mode to do the repetitive parts of the build. I am almost 66, and looking forward SO much to continuing to learn from you, and Mathias, and Steve, and so many others who show me how to do stuff that I have dreamt about for years. Not growing up with any experience like this, and having struggled with magazines where they tell you 85% of what you need to know, and assuming that the other 15% is knowledge I already have (which I didn’t) was exceptionally frustrating. Your posts, and the others like it, are the hands on help I have needed without having to apprentice, or leave my house!

Keep up the thinking, and planning, and sharing. You are a great help to people like me.

Jay…..you surely are an inspiration! You make everything look so easy. Just wondering how many hours did it take you to cut and assemble all those drawers? It would have taken me a week (I work really slow :). Keep up the great work an videos. I look forward to them every week.

I honestly didn’t keep up with the time. A total guess would be 15 hours? Thanks for the kind words Paul. Much appreciated.

LMFAO you coming out of the draw, you have a lot of talent making these videos. Excellent job on the miter saw station. I’m jealous seeing you work with the garage door open up here in the north east it will probably be June before I can do that the way the weather is going up here

Looks great and I know you will be thrilled using all that clean, empty space they provide. Outstanding job, as usual.

The drawers are fantastic, great job!! I wish I had half the room you do to make these great projects. That’s O.K though at least I have the space I do. Once again very nice work, you make it look so easy.

Good stuff Jay. Lotsa pocket holes. I’m in the middle of doing 3 base cabinets that has 3 drawers in each cabinet and I used the same method with the pocket screws. Fun fun fun! I like the part where you rose up from the bottom drawer. You may have to re-think your placement of your heavy planer as far as it being on the bottom shelf. It may get heavy later on as you get older. :)

Excellent job. Nuff said. Oh, I was really glad to see you use #gluewithpocketholes .

Excellent video. Can’t to see it finished. Am I detecting a bit of influence from Frank Howarth?

Take care, Rik

When I saw all that wood pre-cut in stacks all I could think of was—–“I sure hope he didn’t mess up a measurement”. Great job. What was the total cost for materials???

One of your more cinematic videos. I liked the flow and the different camera angels. Nicely done.

You have got it good on pricing there in the US… here in New Zealand we get “screwed”. Check this out for comparison… http://www.fullie.co.nz/extra-heavy-duty-/15-1350mm-270kg-ball-bearing-runner-1-x-set.html a pair of slides rated similar heavy duty to yours are $270USD here in NZ. You paid $6.50 a pair. Thats why I buy in the US and get them imported … i prefer to wait the month and pay the courier fee.

Hi Guy

looking at the rails used in this fantastic project look more like these:

http://www.fullie.co.nz/drawer-runners-/88-600mm-b-b-runner-45kg-1-set.html

I can see your point about pricing, but there is no comparison in the market size and volume sales between New Zealand and the USA. However, if you ever need a good price give me a call

So the drawer with you in it is the ‘honey do’ drawer!?? That is the drawer that the wife uses to get you out of and put you to work, or is it the drawer that you hide in to stay out of her way???

Excelent job and excellent video. Congratulations and many thanks to share this with us.

I wonder about one thing; wouldn’t it be safer to find a system to be able able to open only one drawer at the time (at least one drawer per series of 3)? This to avoid a misbalance.

All the best.

I’m not sure I understand what you are asking. The drawer boxes are mounted. They will not tip out if you pull all three drawers open at the same time. I’m not sure why anyone would have all three open at the same time though.

I like seeing your personality come through with the new feel of this video. Keep trying new things.

Love your videos simple and to the point, keep up the good work.

Jay I really enjoy watching your projects video, I thought I knew I a lot BUT I have learn a lot of shortcuts from your videos , I check out outwater on the drawer slides and there where the cheapest, so I order some , then I get a email telling the shipping was the wrong price they wanted 40 dollars to ship 15 slides instead on the 15 dollars on there web site. So I cancelled and order them off EBAY , I have order slides off ebay before and to me they look and work great 10 slides were 68 dollars including shipping , Keep up ALL the great videos and thanks a lot for all the hints and tricks

Hi Jay,

I’m building some large drawers for some utility room shelving I’m building, and your process has been invaluable!

You mentioned you used 3/4″ ply for the bottoms…did you use the same for the front/back/sides? I have sides that are a little over 1/2″ and was planning to do 3/4 for the bottom. The drawers are going to be rather large…40″ wide, 28″ long, and 9″ deep. Will 1/2″ work for the sides?

In honesty…I had a full sheet of plywood lying around so I cut that up and sized everything for the the front/back/sides. It was at that point I realized it was only 19/32″ :(

Thank you!

Ross

Jay,

My question is regarding your drawers…. 37 seconds into your video you put 2 18″ spacers to mount the drawer slides. Then, 11-1/4″, and finally, 4-1/2″ spacers. Why did you choose those numbers? Is it based on the size of your drawer boxes?

Thanks in advance,

Rich

Jay,

Love your vids and projects. I have found AHTurf has excellent prices on slides. As I interpret prices from AHTurf and Outwater Plastics, 10 pair 20″ 100# from AH is 4.06/pair vs 5.07/pair from Outwater; both plus freight and screws. Hope this helps.

Thanks for all you do to promote woodworking and safety!!

Bob

Hi Jay, love your videos! I was so happy to see a video of STRONG drawers where the bottoms did not use a dado (I don’t have a table saw or router table). I am about to do a drawer project myself for the first time and am trying to decide between your method of securing the drawer bottoms or using pocket holes. What would you recommend?

Thanks!

If you’re not worried about how the drawers will look on the sides I would just glue and screw the bottom panel on from below. Predrill the screw holes so you don’t split the plywood.