Its funny how things work out sometimes. When I made my table saw station I had the notion that it would be my first and only. Well as of now it is my only and I do not plan on making another. The simple fact is that our needs and wants change. The main reason for the table saw change is I made the table saw station too big for my shop. Maybe not too big if woodworking was all I did in there but when you throw in moving the light stands and the camera around it was definitely a pain in the butt to maneuver around. I could either buy a new saw or dismantle the old saw station and start over. Taking it apart and starting over seemed silly as nothing was wrong with it. I put too much hard work into getting it the way it was.

I also wanted to re-make a few of my table saw jigs but with the current ones working OK I never really pushed to do so. Here recently I’ve also come up with a few neat router table ideas that I would like to expiriment with. Now that I don’t have a router table anymore I might be able to do so.

So…I sold it and bought a new saw. The new owner of my Porter-Cable got a sweet table saw station with a bunch of already made jigs and I got a smaller, much easier to move around and store away table saw with the potential of more upcoming fun shop projects. Sometimes change is good. This is a win-win situation.

RIDGID R4512

My intention was to get the same Porter-Cable saw I had but to my surprise the blue store replaced it with a goofy looking Delta saw. I wasn’t too thrilled with the display model that I saw so I made a trip up to the orange store to look at the RIDGID R4512. It looked to be nearly identical to my Porter-Cable so I bought it (update at the end of this article, I returned it). Boy am I glad for the invention of an appliance dolly. These saws are HEAVY!

Opening the box. Lovely smell of shipping grease and all the parts in their own cozy, non-biodegradable compartments.

And all the parts laid out ready for assembly.

Step 1 was to place the saw upside down on a few wood runners. The saw was going to be assembled upside down. Moving this thing around by myself wasn’t fun.

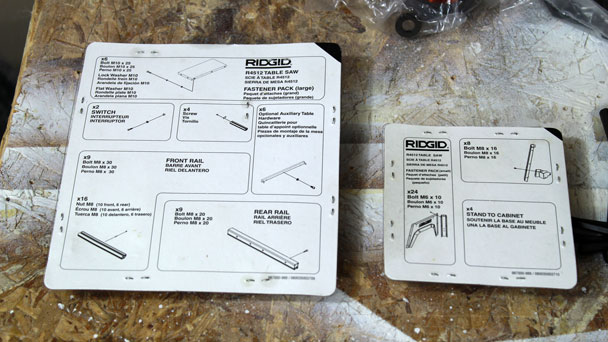

I like it when tool companies package the hardware like this. Having everything jumbled up in a bag really sucks when the instructions say “use two bolts labeled E with two nuts labeled M.” This is much more user friendly.

First the wings get lightly bolted on. And a cameo appearance of my cell phone.

The base gets bolted together separate of the top.

The included 4” dust collection port is optional. I have a 4” dust collection hose that is dying to hook up with it so I decided to install it. Top, dust collection port, then the stand. Four bolts hold this sandwich together.

Next the caster assembly is bolted to the stand, the fence storage brackets get bolted to the cabinet body, and the stylish shoes snap on.

Between the last pic and this next one the saw needed to be flipped on its stand. This is one of those jobs where if done by yourself you’re either going to A get a hernia or B accidentally let one rip. Luckily A didn’t happen and I was able to install the front and back rail and make sure the tables were flush with the cast iron.

The part of every tool purchase that I dread is getting rid of all that nasty shipping grease. A wipe down with mineral spirits quickly removes all the built up grease. Followed by a few wipes with lacquer thinner to remove all the residue. And a coat of cheap wax for protection.

Next I checked alignment of the blade to the miter slots. It was .010” out from front to back of the blade. I was dreading this as all of the very few negative reviews this saw has relate to the inability to get the saw blade parallel to the miter slots.

After reading further into the assembly paperwork I found the blade alignment to be quite easy actually. By taking the back cover off you can easily access four trunnion bolts to adjust alignment. I’m not sure if this is something that was added or changed somewhere down the line but I had absolutely no problems with aligning the blade.

And checking the blade to be square to the table top. The stops seemed to be accurate from the factory here.

The last thing to adjust is the fence. It too needs to be parallel to the miter slot. Adjustment is made by four bolts connecting the actual fence rail to the fence body.

To answer a few questions that you probably have. Is this RIDGID a better table saw than my Porter-Cable? I don’t think so. Is the Porter-Cable a better table saw than this RIDGID? I don’t think so. The Porter-Cable had a couple areas that I like more and this RIDGID has a couple areas that I like more. Looking at the big picture the saws are pretty much the same. Both are a great option for the price range. Remember that I was originally going to replace the Porter-Cable with the exact same model. This is one of those situations where us as consumers are fortunate to have competition between companies to produce another saw in the same budget range that offers pretty much the same quality.

***UPDATE***

Well folks, things took a big turn with the new table saw. I checked and checked and checked to make sure I didn’t have the trunnion issues associated with this saw. Apparently either I didn’t check good enough or something happened after a couple days because I noticed it big time today. When raising the blade the blade will tilt to the right by a few degrees and when lowering it will tilt to the left by a few degrees.

This saw has a boat load of awesome reviews on various sources online and nearly all of the few negative reviews point to this issue. So that tells me I got a lemon.

I contacted Ridgid and they know the exact problem and say it is a bad trunnion that needs to be replaced. My options are to drop the saw off at an Orange store for them to ship it off to be replaced, return it for another one and risk the hour drive each way to see if it has the same problem, or drive to an authorized repair location. Either way I have to make multiple hour long trips to get the problem situated and could possibly be out of a saw for who knows how long while it gets repaired. No thanks. I’m returning the saw this weekend and will be spending more time this go around looking for a replacement.

If they fix this issue permanently I’d give it two big thumbs up. Pretty good saw if you get a good one. I didn’t and I don’t want to waste my time making it a good one.

Jay, thanks for he article on the Ridgid tablesaw. I’m in a similar situation and this Ridgid is on my short list. Your article has really helped!

Total envy man! That is the saw I originally wanted to buy but my budget wouldn’t allow it. And the fact that it would be too big for my garage. So I ended up getting the R4510 on sale. So far I love this saw and it’s features, especially the storage were it folds down. Good luck with your new saw and hope it delivers quality cuts.

Jose

I GOT MY R 4510 LAST YEAR THE REASON WAS THE 150 LBS LIGHTER THEN R4512 I DONT EVEN HAVE A GARAGE i HAVE A BACK PORCH AND A INSIDE PORCH/ROOM FOR THE WASHER AND DRYER AND OTHER STORAGE SENSE I COULDNT AND WOULDNT BE ABLE TO GET THE 250LBS BEAST IN THE HOUSE(INSIDE PORCH) WHEN DONE WITH IT ,i WENT WITH 95LBS R4510, MAYBE ONE DAY i CAN MAKE ONE THE FANCY CABINETS FOR IT AND UP GRADE THE FENCE/MITER , I’M CURRENTLY LOOKING AT IDEAS/ PLANS ON BUILDING A MITER STATION THAT MY JOINTER AND PLANER CAN FIT UNDER AND HAVE LOCKING DOORS .. I REALLY LIKE THE LSA WARRANTY FOR LIFE! WE HAVE A BLUE STORE , ORANGE STORE (ACROSS THE STREET FROM EACH OTHER AND OREGON TOOL STORE(*JET DEALER)ALL 3 JUST 17 MILES AWAY

You should have made a video on how to square everything up. I need to adjust my blade but I am at total loss as to how to measure it to see how far out it is.

Jay did you catch the date code on your box. Should be “EM####”. I’m wondering if the newer the saw the lesser the blade alignment issues.

EM1337. I had zero issues aligning the blade. 4 easy to access adjustment bolts.

Awesome. This is the exact saw I was going to buy. Although I have to drive 83 miles (one way) to get it because, apparently, the orange store doesn’t like woodworkers in SW Florida.

I know the feeling. I drove 75 miles to get this one.

I’ve been looking at that exact saw the last couple times I’ve been at home depot and was looking for feedback from another woodworker on their thoughts about the Ridgid table saw. Thanks, might be picking this up in the near future.

I like your new table saw. I look at it every time I’m at the orange store. I have two table saws, an old Jet JTAS-10X-1W and a Rigid 2400-1 (which has been replaced by the R4510). The Jet is old but very good still. The Rigid came out of the box square and parallel. It’s now my dedicated dado saw. What did you do with your Porter Cable?

Thanks for posting this info. I’d very interested in a follow-up review in a couple of months. I’ve been debating on getting a “budget” saw like this or saving my pennies for a lot longer and getting the cheapest professional saw I could afford. Currently I have an old Craftsman inherited from my grandfather but the fence is complete garbage.

I have the same saw and absolutly love it.

What was it about the Delta TS did you not like?

oops forgot to say GOOD LUCK with it. Can’t wait to see the first project you do with it.

I too have the same question. There unfortunately isn’t much info on the new Delta 36-725.

Nice looking saw, Jay. I have a 10 yr old Rigid TS2424 that has seen better days. I’m curious to see how long it takes you to replace those stamped steel wings with something more useful. Congrats on the new saw!

I like your new saw, I too just purchased a new table saw but I ended up getting the craftsman 10 inch contractor saw. ( item # 21833 ) It looks a lot like yours. I haven’t got to use it yet due to shoulder surgery but I did play a little and try it out. I really like it. Can’t wait to see your first project with it.

Thnx for your in depth review.

Great saw! I purchased mine about the same time you did. I built an outfeed and router table for mine.

https://plus.google.com/photos/117066676979591384125/albums/5984348558740784785

I can’t wait to watch your videos and see what you make with it.

Ugh Jay that sucks! At this point it’s probably less about the saw and more about all the wasted time.

Thanks jay. I bought the same saw last week. It’s my first table saw but definitely not the first I have used. I love it. I haven’t had any problems however I do have some gross looking grease stain on the top. I haven’t called Rigid to discuss it but I’m with you this thing is heavy and I’m not willing to take it apart for a replacement. I’m going to clean with spirits and see if that will help.

From what i’ve seen on the internet, and on my saw, the grease stain is common. I can’t explain what it is though. I rubbed most of it out with Simple Green.

Jay, sorry to hear you have the blade alignment issues. I’ve had my R4512 over a year and have had no issues. I read many reviews before purchasing so the first thing I checked (and have rechecked several times in the last year) was the up/down alignment. Raising and lowering the blade on mine shifts it by less than .001. Guess I got lucky (or not unlucky).

I believe the problem develops because they’re shipped upside-down. The weight of the motor bends a mount. That’s neither here nor there–if you get one with the problem it’s a problem.

For anyone considering buying a R4512–they’re good saws. IF you get one that runs true. Mine does and I’m very happy with it. It’s an excellent saw for the garage woodworker, and it doesn’t break the bank to buy.

Hey magus is this saw a belt driven motor

It is a belt driven motor.

Man! I just bought one of these – I mean like a week ago – haven’t had time to use it though. I have it setup but still tuning it. I did notice that the blade was out of alignment. I worked on it some but still have to tweak it some more. Haven’t checked the trunnion issue yet. [Praying i don’t have the same issues…]

Why don’t you try a Grizzly table saw? They made that awesome band saw you have. If you have about $1500 you can get a low end Saw Stop. Then you can make a hot dog video to test the saw stop out! That would be cool!

Hi Jay,

Thanks for sharing your experience with us. Lot’s of us have the question of whether to get a saw at this price point or spend more money. Looking forward to your next saw. Hope it works better.

I have owned this saw for a year. Mine wouldn’t align. I called and came up with about a month of craziness. I decided to deal with it myself. I had to take the trunnions out and grind them. Everything is dead on and wonderful since that point. Hope your second attempt at a new saw will be much better.

Jay

I’ve been watching your videos for a while now and really enjoy them. I can relate to space issues, as I moved my shop from a 2 car garage to a one car garage about a year ago. Now trying to decide if I can part with my radial arm saw because of space issues. Tough decisions.

Good luck on you endeavors.

Man that stinks. I think there is a delta saw in about that price point. let us know because most of us are in the same bag. What better tools at an affordable price.

Jay – I noticed that you are using your kitchen as a woodshop. I made sure I showed my wife this in hopes that she would relent and let me do the same but to no avail she told me hell no. I have the RIDGID 10″ Compound Sliding Miter Saw and it is a little off also. It may not actually be the alignment but the laser. I have not had a chance to do a proper alignment yet but the instructions state that it should be factory aligned. I like RIDGID tools and do have quite a bit but the table saw that I will purchase in the coming months is the Professional Series SAW Stop. Quite a hefty price but my hot dog weenie fingers won’t get removed in case I have a brain fart.

Well to follow up my previous post about my new R4512 – i have tuned it up and mad a few cuts (made a sled and some shop stuff). it seems to be working and aligned well so far. I have heard tales of people getting this saw and having issues – and then those who get one and have none. Jay – what have you done with the saw? Did you return it or did you finally tune it?

I’m sorry to hear that you had problems with your saw, but I’m glad you were able to get a different one that works for you. I bought my 4512 a few months ago and used a harbor freight 25% off coupon. So far I have had no issues with it apart from popping the breakers once.

Sorry to hear you had issues. I bought the same one in November. Put it all together and didnt need any allignment at all. Everything was dead square. No issues with the blade moving either. I guess I got lucky. The only thing I dont like is the fence. Everytime I lock it down it moves about 1/16 to an 1/8th towards the blade at the oposite side of the locking lever. I cant figure out why or how to adjust it.

Looks like this is a mixed bag table saw – some of us get lemons and some peaches. Too bad, there seems to not be many choices for “mid-range” table saws (somewhere between a $1k cabinet and a $200 contractor). Since I have the R4512 (with no know issues – yet) I’ll keep all of us R4512 owners in my prayers…

We may need it – and judging from Jay’s experience with his new Grizzly – he needs it too.

I had the same issues, and it’s funny cause I went to the blue store to get a Porter Cable just like you did. When the Ridgid didn’t work out I went ahead and tried with the Delta, and I am very happy with it. The fence is pretty nice for a stock fence in this price range.

I had one a few years ago and it was the best table saw I’ve had the pleasure to use, and I’m ready to buy it again (lost last one in divorce) love this saw and hope I don’t have an issue but I’m going to take a chance because I know it very well, sorry yoy got a lemon, nothing sucks more!

Jay, I bought this same saw about eight months ago. I’m still new to woodworking as a good hobby, but figured this saw to be about the best in the price range for me. I’m still learning and have had just a few small issues with alignment and the fence being out of square. Thanks for giving me a simple and straightforward intro on how to correct these minor problems. Also, didn’t know any thing about or even to watch for the trunnion problems. Thanx for the info.

I GOT MY R 4510 LAST YEAR THE REASON WAS THE 150 LBS LIGHTER THEN R4512 I DONT EVEN HAVE A GARAGE i HAVE A BACK PORCH AND A INSIDE PORCH/ROOM FOR THE WASHER AND DRYER AND OTHER STORAGE SENSE I COULDNT AND WOULDNT BE ABLE TO GET THE 250LBS BEAST IN THE HOUSE(INSIDE PORCH) WHEN DONE WITH IT ,i WENT WITH 95LBS R4510, MAYBE ONE DAY i CAN MAKE ONE THE FANCY CABINETS FOR IT AND UP GRADE THE FENCE/MITER , I’M CURRENTLY LOOKING AT IDEAS/ PLANS ON BUILDING A MITER STATION THAT MY JOINTER AND PLANER CAN FIT UNDER AND HAVE LOCKING DOORS .. I REALLY LIKE THE LSA WARRANTY FOR LIFE! WE HAVE A BLUE STORE , ORANGE STORE (ACROSS THE STREET FROM EACH OTHER AND OREGON TOOL STORE(*JET DEALER)ALL 3 JUST 17 MILES AWAY

Hey guys is this saw a belt driven motor?

Yes, it is belt driven.

I have had this saw for about 3 years I generally I like it. Over time I have found a few things that really irritate me about it. Overall it has a decent amount of power, but I really have to slow down when cutting hard woods (might be a little due to my blade). The two major stones I have to throw are about the fence and the insert area. The fence has a two point clamp one up front and one on back rail. After using for a while I noticed it stopped clamping square, so I would have to do the measure front back and bump method; gets old. So, I am replacing fence system with the very super cool tools system. The insert “shelf” that holds the blade insert has these little circle bump outs that hold the leveling screws. They create a problem when making zero clearance inserts, so I go ahead and make a few at a time. I havent found a great way of making them yet beside using a forstner bit and hacking away at it. Like I said those are the only two issues I had, but they deal with major parts of the saw.

what did you get? does anyone know if the problem was fixed by manufacture? i am looking to grab one.. soon.

I read a statement from the manufacturer saying the problem was fixed after a certain date. Mine was manufactured AFTER that date and still had the problem. Not sure about it’s current state. I ended up getting this: https://jayscustomcreations.com/2014/10/thoughts-on-my-grizzly-g0690-table-saw/

I just bought this saw today. I read reviews zND I figured I would take the plunge. I just got it set up, can’t wait to use it

Hey jay I purchased this saw not long after Christmas how noticeable was the left and right tilting when raising and lowering the blade?

I could visibly see it. Measured to be about .015″ with a dial indicator.

Thanks! I don’t currently own a dial indicator (will be purchasing soon) I upgraded to this saw from a very very cheap bench top that I got from an auction so it’s amazing to me so far. Just have my fingers crossed that’s mine doesn’t have the issue.

well, just confirmed it last night, after weeks of trying to get the blade square, no go! need to figure out what to do now, return it and get the same model and hope all is good, or get Ridgid to repair, or return and buy a different saw…. it sounds so simple to type this, yet hours worth of time to do so :(

It’s really an unfortunate situation. Due to the large amount of people experiencing this problem I decided to get my money back and go elsewhere.

Jay, have you decided yet on which saw to buy?

I bought this one: https://jayscustomcreations.com/2014/10/thoughts-on-my-grizzly-g0690-table-saw/

I purchased this saw today after reading all the reviews about the similar problem. all the new reviews state that Rigid has corrected the problem with a heavier trunnion bracket. When I got home I opened the box to check before unpacking. And during movement the motor would shift. I thought I got a bad one. Come to find out there was a large block of Styrofoam under the motor for shipping. I removed that and everything was good. Haven’t used it yet but fingers crossed.

Thank you for the review. As I’m sitting here in my garage looking at the 36 year old “old faithful” craftsman that JUST burned up, reading your review will defiantly help my decesion. Now, how is it again to explain to my wife that I NEED a $500 table saw??? :)

I’m thinking very seriously about buying the R4512. I wrote Ridgid to see if they have made an effort to correct the problem with the trunnions and the email I received said, “There are no known problem or issues effecting RIDGID table saw model R4512 as a whole, for there to be some type of updates or improvements created for.” This is the same thing they write on their website under the Q@A section when asked about the problem. I wrote Ridgid back and asked them for specific information on the trunnion issue. I told them safety and accuracy is very important to me and I will not be spending my money with them until they tell me if they fixed the problem. I hope they give me a straight answer, otherwise I’ll take my business elsewhere.

Hey Jacob, any updates from Ridgid on the trunnion issue? I’m considering this saw, but this issue definitely has me put off a bit..

I actually got a great one! So, it just depends, I think they have fixed the issue, just a heads up.

What is the final assembled WxLxH dimension of the Saw. I need to make sure it will go through my basement back doors lol

I purchased this saw and mine was with no defect. Seems maybe yours was a one in million but that happens. I am very happy with this saw and would recommend it.

Well I bought this saw today and after doing the assembly to the point of turning it right side up found a couple small dings in the edge of the cast iron table. I got out my stones and smoothed them out and figured I would check the alignment of the blade etc before I went further. Good thing I did. I started to check the blade alignment and noticed my straight edge was hitting on the right side miter slot edge. I grabbed my test indicator and stand and found the cast iron top was nowhere close to being flat. The right side beyond that miter slot is .0025″ higher than the center. To make matters worse the left side past the left miter slot is .006″ lower than the center of the table. That is a total of .0085″ off, so then I checked the front to back on the table and found it to be off as well by between .003 and .004″. I was an aerospace calibration specialist for 15 years and this really shocked me. I am calling Ridgid tomorrow and if I don’t get a satisfactory soloution it will be going back to the store which is unfortunate because I was given 20% off the normal price by the store manager.

I will post again when something happens.

Ok follow up to my comment above.

I contacted Ridgid and they were absolutely no help… bottom line they said just return it and get another one. So I called the store and spoke with the manager whom I dealt with the day before and explained to him the problem.

He was very cool and said if you want to just take the main body assembly off and bring it in he would be glad to bring down a couple other units and I could open them up, test them, and pick the best one as a replacement.

He even had them ready when I got to the store and had a couple guys unload the bad one from my vehicle. The first one I checked the table was very good but had the trunnion issue and I explained that problem to him and he called “His” Ridgid rep to come over and look at it. About 20 minutes later the rep showed up and started going over everything with me and documented it all for a report he was going to file with Ridgid. The second unit we checked had a good table and no trunnion issue, they helped me load the new table / motor assembly back into my vehicle and I said thank you very much!

After taking the rest of this afternoon finishing all the set up and double checking everything, I have to say setting up the 2 piece guide assembly was a pain. The blade was parallel with miter slot within .001 – .002″, the fence was within .001″, The blade angle at 0 degree was off by about .1 degree and the 45 was off about the same. The miter track to miter gage fit was less than .001″ side to side on the left miter and less than .002″ on the right one. Over all table flatness was great, I measured less than .0015″ deviation everywhere I checked.

Hopefully this will last me for many years.

I have to say HD went above and beyond for me.

@ Todd …….. Your account of the events was great. Thanks for posting it. I have this saw since June 2011 and I love it. I didn’t have the blade and miter problems mentioned. I did, however, upgrade my fence rails from the 2-piece to a Vega Pro 40 fence system. In retrospect, I wish I had gotten a T-Square Style simply because they “seem” to be the best option available. 20 / 20 hindsight. None the less, I still love this saw.

What is the horsepower of this saw?

Jay, what saw did you end up with? Will you do a blog or video about it?

Check this out: https://jayscustomcreations.com/2015/12/tool-talk-5-sawstop-pcs-vs-grizzly-g0690/

Well despite all the bad reviews I kinda had bo choice but to buy one of these POS rigid R4512 started assembling it this morning around 8 am. By 2pm today she was on her feet and I was adjusting the rails , fence square.. blade square to miter slots and fence everything tight and right by 4 pm. Turn it on runs amazing!! Make a cut I was some what impressed .. NOT!!! 5 cuts later half way thru a cut it starts to vibrate a little more then it had.. I manage to get the piece thru shut off the saw.. unplug it and take off the throat plate I look inside and notice to the left my drive belt is moved over 2 grooves towards the inside to the motor. Take of back cover and far back truinnion bolt is cockeyed looking and I can see a gap after a little more investigation they shimmied just that side with a thick washer.. I’m take it apart now to return it in the morning… my favorite part is that not only a table saw is how I make my living but I also had a hernia surgery 3 weeks ago and has buddy’s help me with the lifting .. but I have to take apart and load it alone.. screw this saw!!! dont buy it!!!!